- sale@instructrobot.com

- Dallas, TX , United States

As the demand for automation grows, understanding the palletizing robot cost becomes crucial. Industry expert Dr. Emily Carter emphasizes, “Investing in automation can dramatically reduce labor costs.” This statement echoes the sentiments of many manufacturers seeking efficiency in operations.

Palletizing robots are essential in today's fast-paced industrial landscape. They streamline the packaging process and enhance productivity. However, evaluating the costs associated with these robots is complex. Each installation brings its unique challenges and potential hidden expenses.

Future trends indicate that costs may fluctuate due to technological advancements. Innovations could potentially lower initial expenses while increasing functionality. As Dr. Carter warns, “Companies must carefully assess long-term impacts, not just upfront costs.” This insight reveals the necessity for a comprehensive understanding of palletizing robot cost and its potential long-term benefits.

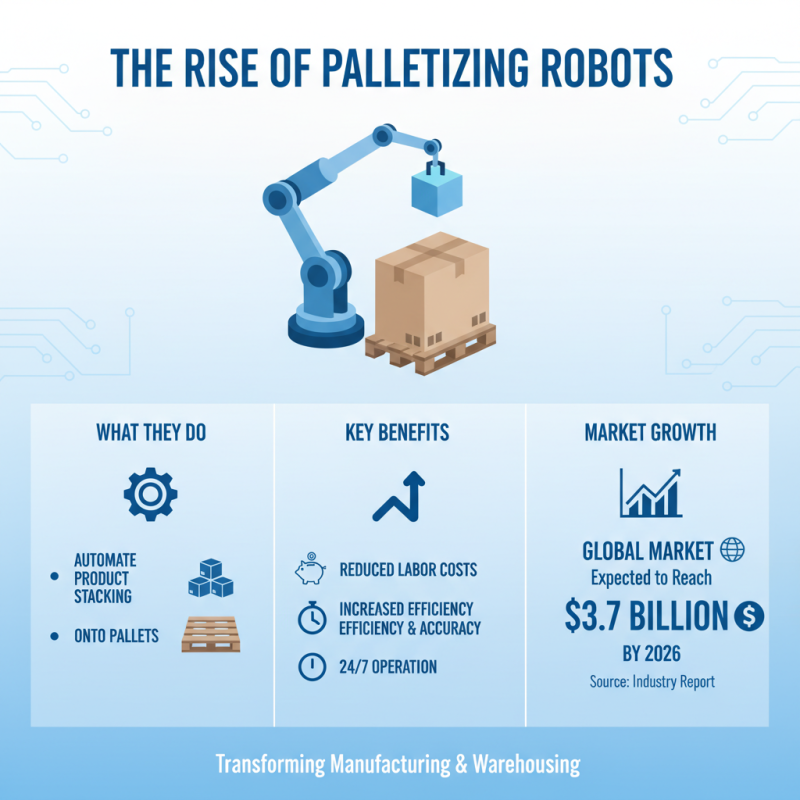

Palletizing robots are transforming the manufacturing landscape. They're designed to automate the stacking of products onto pallets. This automation reduces labor costs. According to a recent industry report, the global palletizing robot market is expected to reach $3.7 billion by 2026. This growth reflects a rising demand for efficiency and accuracy in warehouses.

Key features of modern palletizing robots include advanced vision systems and adaptable end-of-arm tools. These features allow them to handle a variety of products. For instance, some robots can manage fragile items without damage. Applications span multiple industries, including food and beverage, pharmaceuticals, and consumer goods. However, while automation offers benefits, the initial investment can be high. Companies must evaluate their specific needs carefully.

Future trends indicate continued advancements in AI and machine learning within robotics. This could enhance decision-making processes. Nonetheless, the integration of such technologies often brings challenges. Organizations need time to adapt to these changes. Balancing the cost of investment with operational efficiency remains a critical consideration for many businesses.

When analyzing the expenses tied to palletizing robots, several key factors emerge. Initial purchase costs are significant. High-quality robots often require substantial investment. However, this isn't the only expense. Installation and training add to the budget. Companies may overlook these costs, leading to unexpected financial strain.

Maintenance is another critical area for cost analysis. Regular servicing ensures optimal performance. Neglecting this can lead to costly downtimes. Parts and repair services also contribute to overall expenses. Shortcuts may seem tempting, but they can result in long-term issues and more significant costs.

Energy consumption is often underestimated. Efficient robots use less power. However, inefficiencies in the system can lead to higher bills. Factoring in the training of staff on operational efficiency is key. Many organizations forget to budget for ongoing education, which can hinder ROI on the initial investment. Each of these elements deserves careful reflection when planning a palletizing operation.

| Cost Component | Estimated Cost (USD) | Percentage of Total Cost |

|---|---|---|

| Robot Unit Cost | $50,000 | 40% |

| Installation and Setup | $10,000 | 8% |

| Maintenance and Support | $5,000/year | 4% |

| Energy Consumption | $3,000/year | 2.4% |

| Training Costs | $2,000 | 1.6% |

| End-of-Life Costs | $5,000 | 4% |

| Total Cost | $75,000 | 100% |

The palletizing robot market is transforming rapidly. Innovations drive efficiency and productivity. One crucial trend is the integration of artificial intelligence. AI enhances decision-making, making robots smarter. They can adapt to different loads and environments easily. This flexibility is vital for manufacturers.

Another exciting development is collaborative robotics. These robots work alongside humans. They create a safer working environment. However, challenges remain. Proper training and adjustments are necessary for smooth collaboration. Companies must invest time to integrate these systems effectively.

Finally, the rise of industry 4.0 is influencing palletizing robots. Real-time data analytics optimize performance. However, the transition can be complex. Companies might face resistance from staff or technical limitations. Embracing these innovations is not always straightforward. Yet, the potential benefits are too significant to ignore. The future of palletizing robots is bright but requires thoughtful execution.

The investment in palletizing robots has shown impressive returns compared to manual labor. According to recent industry reports, a palletizing robot's average ROI can reach 75% within three years. This starkly contrasts with the limitations of manual labor, where productivity often fluctuates due to human error and fatigue. Implementing automation can significantly reduce labor costs and increase efficiency in production lines.

However, the transition to automation is not without challenges. Many companies face upfront equipment costs and integration complexities. Studies indicate that the initial investment for a high-quality robot can exceed $100,000. While this may deter some industries, the long-term savings are substantial. Robots consistently outperform manual workers in speed and accuracy, completing tasks with minimal downtime. Yet, it's essential to consider the ongoing maintenance and potential for technological obsolescence, which can affect the overall cost-effectiveness.

Interestingly, the benefits of palletizing robots go beyond just cost savings. They facilitate safer work environments by reducing the risk of workplace injuries common with manual handling. However, businesses need to adapt their workforce accordingly. Workers may require retraining for new roles, which can disrupt existing workflows. Balancing automation and human labor is crucial for sustainable growth in the industry.

As industries evolve, the demand for palletizing robots is increasing significantly. By 2026, projections indicate a substantial rise in adoption across sectors like food and beverage, pharmaceuticals, and consumer goods. Companies are recognizing the benefits of automation. This shift is driven by the need for efficiency and precision.

Tips: Consider your specific needs before investing. Analyze your production volume and the types of products you handle. Not all robots fit every operation.

Some companies may underestimate the costs involved. Initial purchasing costs can be high, but long-term savings on labor and error reduction will likely outweigh this. It's essential to budget for maintenance as well. Develop a strategy that accounts for both immediate needs and future scalability.

Tips: Look into financing options and grants. Some programs support automation in small to mid-sized businesses. Don’t overlook these potential resources; they can ease the financial burden. Implement training programs for staff to maximize the benefits of new technology.