- sale@instructrobot.com

- Dallas, TX , United States

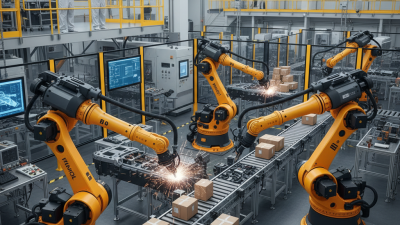

The assembly robots sector is rapidly evolving. Innovations are reshaping production lines. According to a recent report by MarketsandMarkets, the assembly robots market is projected to reach $23 billion by 2026. This growth is driven by increasing automation across various industries. Companies are adopting assembly robots to enhance efficiency and reduce labor costs.

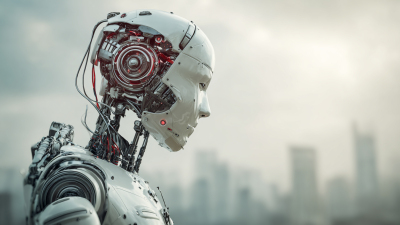

Recent trends highlight advancements in AI and machine learning. These technologies enable robots to adapt to complex tasks, increasing their versatility. Reports indicate that over 60% of manufacturers plan to invest in innovative robotic solutions by 2025. Yet, challenges remain. Standardization across different platforms can hinder integration. Additionally, there is an ongoing debate about job displacement as automation rises.

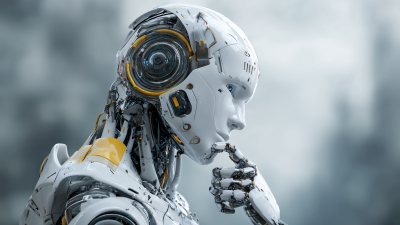

The focus on collaborative robots, or cobots, is becoming essential. These robots work alongside humans in assembly tasks. Their ability to handle delicate components is notable. However, the effectiveness of assembly robots still relies on skilled human oversight. The balance between automation and human labor needs careful consideration as we move forward.

The landscape of assembly robotics is evolving rapidly. According to a recent industry report, the global assembly robot market is projected to reach $24.5 billion by 2026. This surge reflects the increasing adoption of innovative technologies in automation.

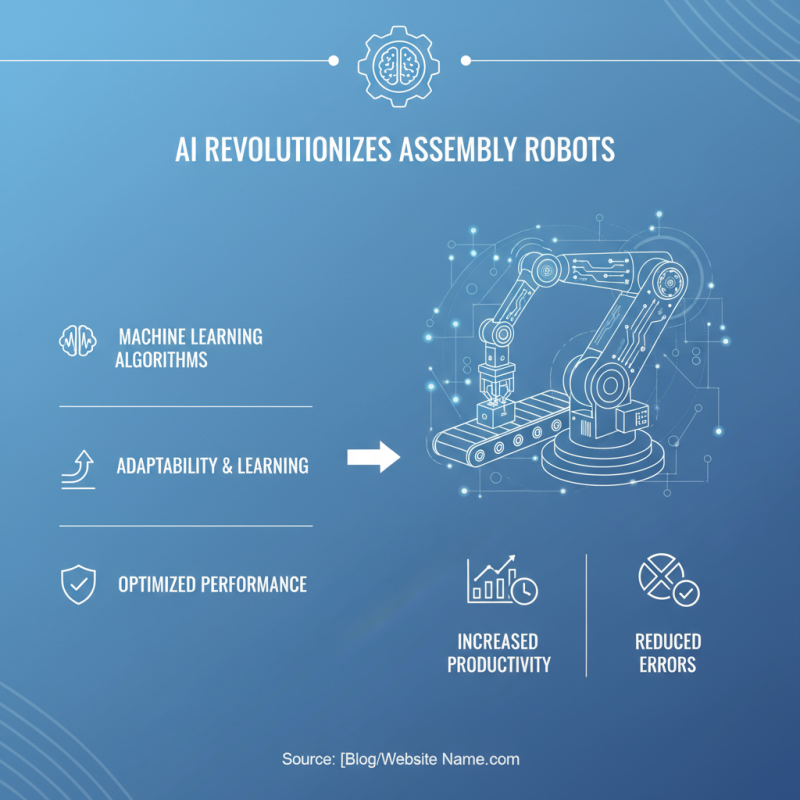

One prominent trend is the integration of artificial intelligence (AI) in robotic systems. AI enhances robots' capabilities, enabling them to learn from their environments. This adaptability leads to greater efficiency and reduced error rates. However, the reliance on AI raises concerns about reliability in unpredictable situations. Additionally, many manufacturers face challenges in implementing these advanced systems effectively.

Collaborative robots, or cobots, are gaining traction as well. These robots work alongside human operators in shared spaces. The market share for cobots is expected to grow significantly, possibly exceeding $7 billion by 2024. Yet, ensuring safety in these environments remains a critical issue. Balancing human and robotic interactions requires ongoing assessment and refinement. Effective training for humans working with cobots is essential to prevent accidents and optimize workflow.

As we approach 2026, assembly robots are set to experience significant innovations. One key trend is the rise of collaborative robots, known as cobots. These robots can work alongside human operators, enhancing productivity. According to a recent industry report, the global cobot market is projected to grow by 23% annually, highlighting the increasing demand for safer and more efficient automation solutions.

Another trend is the integration of artificial intelligence in assembly robots. AI enables robots to learn from their environments, improving adaptability. This allows for better decision-making processes. A study by a leading automation research firm estimates that AI-equipped robots could reduce assembly time by 30%. However, implementing AI also raises questions about training and data management. Companies must consider these challenges.

**Tips:** When selecting assembly robots, assess the compatibility with your current system. Ensure that your team receives adequate training. Experiment with pilot programs before fully committing.

The incorporation of advanced sensors is also noteworthy. These sensors enhance precision and enable real-time monitoring. Companies can expect a dramatic reduction in error rates. Yet, businesses must remain open to feedback regarding these technologies. Continuous improvement is essential in this fast-evolving field.

| Innovation/Trend | Description | Impact on Automation | Expected Adoption Rate (%) |

|---|---|---|---|

| AI-Powered Robotics | Integration of advanced AI algorithms for enhanced decision-making capabilities. | Improves efficiency and adaptability in assembly processes. | 75% |

| Collaborative Robots (Cobots) | Robots designed to work alongside humans for safer and more flexible environments. | Enhances human-robot collaboration and reduces workplace injuries. | 65% |

| IoT Integration | Utilizing the Internet of Things to connect robots and enhance communication. | Facilitates real-time data analysis and predictive maintenance. | 70% |

| Modular Robotic Systems | Robotic systems that can be easily customized and reconfigured for various tasks. | Increases flexibility and reduces downtime during transitions. | 60% |

| 3D Printing Integration | Combining assembly robots with 3D printing technology for on-demand production. | Enhances the ability to create complex geometries and reduces waste. | 55% |

The integration of artificial intelligence is revolutionizing the efficiency of assembly robots. With advanced machine learning algorithms, robots can now adapt to changing manufacturing environments. They learn from their experiences and optimize their performance over time. This adaptability leads to increased productivity and reduced errors in assembly processes.

Moreover, the use of AI in robotics allows for precise movements. Robots can now handle delicate components without causing damage. This has become vital in industries like electronics and automotive assembly. However, there are challenges. While AI enhances efficiency, it also raises concerns about job displacement. Workers may feel threatened by the capabilities of these intelligent machines.

Finally, the collaboration between humans and AI-driven robots is crucial. Effective communication between operators and robots can lead to improved outcomes. However, this requires continuous training and adaptation on both sides. As we embrace these innovations, it's clear that while AI brings potential, it also demands careful consideration of its broader impacts.

The rise of collaborative robotics is reshaping assembly line dynamics. These robots enhance human-machine interaction, making tasks safer and more efficient. In fact, a recent report highlights that 78% of manufacturers are investing in collaborative robots to improve productivity by at least 20%. This shift promotes smoother workflows and reduces human error.

Tips: Consider integrating collaborative robots gradually. Start with simple tasks. This approach allows workers to adapt without overwhelming them.

As automation evolves, so does the complexity of tasks. Companies must rethink traditional roles. While collaborative robots assist with repetitive work, humans bring creativity and problem-solving to the table. There's an ongoing debate about trust in machines. Many still feel hesitant about relying on robots for critical operations.

Tips: Address concerns through training sessions. Educating staff on how robots work can increase confidence. Highlighting successes in similar settings can also help.

Understanding this transition is key for companies. The goal should not be total replacement but rather enhancement of human capabilities. A balanced approach ensures that both humans and machines thrive in harmony on the assembly line. Each advancement should be approached with caution, keeping in mind the unique strengths of human workers.

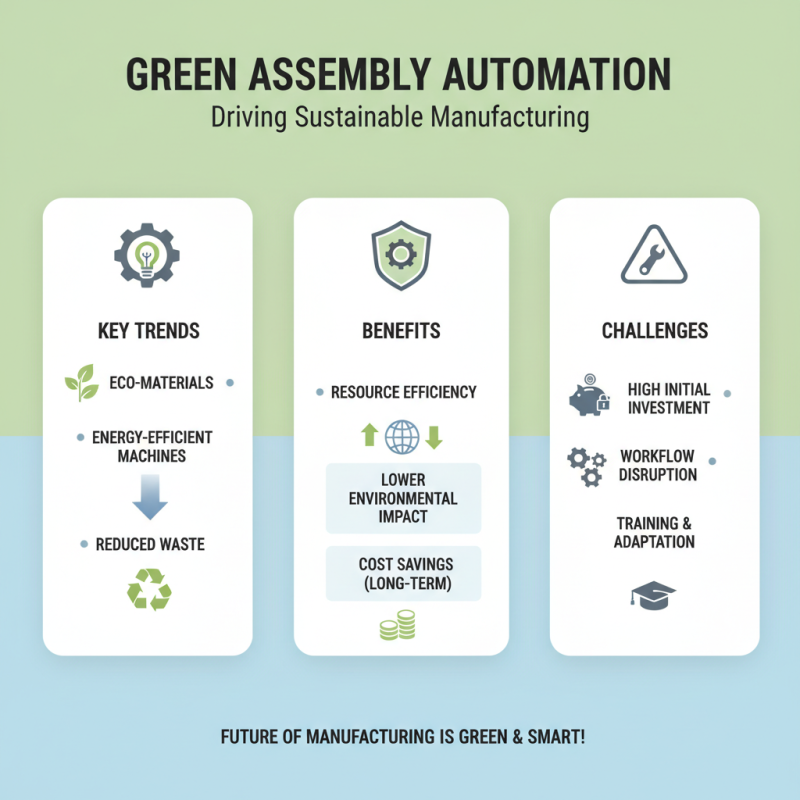

As the world shifts towards sustainability, assembly automation plays a crucial role. Many manufacturers are exploring eco-friendly materials and energy-efficient machines. This trend reduces waste during production. Yet, challenges remain. Not all companies can afford the initial investment. The transition may also disrupt existing workflows.

Innovative assembly robots are increasingly designed with sustainability in mind. They use less energy and produce fewer emissions. Modular systems allow for easy upgrades, enhancing longevity. However, adapting to new technologies is not always straightforward. Workers may need retraining, which can be a significant hurdle.

Furthermore, focusing on sustainability means rethinking practices. Companies must assess their entire supply chain. This includes sourcing materials responsibly and reducing transportation emissions. Change is often met with resistance. Yet, embracing sustainability could lead to improved efficiency and a better corporate image. It’s a complex journey, but one that is necessary for the future.