- sale@instructrobot.com

- Dallas, TX , United States

The landscape of material handling is evolving rapidly. Companies must adapt to new trends to remain competitive. In 2026, various innovations promise to enhance efficiency in this crucial sector. Robotics and automation are gaining momentum. They streamline processes and reduce human error. Smart technologies like IoT will play a vital role. They enable real-time tracking and improve inventory management.

However, the integration of these technologies poses challenges. Many businesses struggle with the initial costs and training needs. Moreover, not every solution fits every company. It is essential to assess the unique needs of each operation. Some may prioritize speed, while others focus on safety.

Embracing these material handling trends can lead to significant improvements. But organizations must remain flexible and open to change. Reflecting on current practices can reveal gaps that need addressing. Ultimately, the future may hinge on how well companies adapt to these shifts.

The landscape of material handling is transforming rapidly. In 2026, several emerging technologies will redefine efficiency in warehouses and supply chains. Automation is a key player. Robotic systems can handle repetitive tasks with precision. Yet, their integration is not without challenges. Training staff to collaborate with robots is essential, but often overlooked.

Artificial intelligence will enhance decision-making processes. Through advanced analytics, companies can optimize inventory and streamline operations. Still, the reliance on technology raises questions about data security and workforce displacement. Finding a balance is not easy. Continuous learning is vital to ensure that human skills evolve alongside machines.

Moreover, sustainability trends are becoming integral. New materials and eco-friendly practices are emerging to reduce environmental impact. However, adapting to these changes takes time and investment. Not every organization can pivot swiftly. Emphasizing both innovation and reflection is crucial to navigate these trends effectively. This evolving scenario calls for an adaptive mindset.

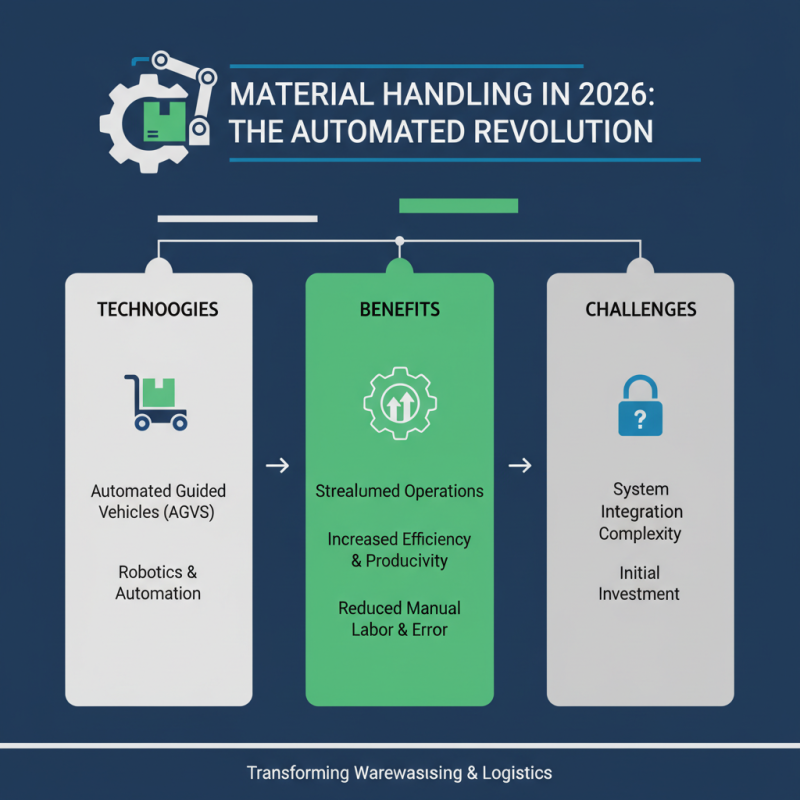

This chart illustrates the projected growth in different emerging technologies shaping material handling efficiency in 2026.

Automation and robotics are transforming material handling systems in 2026. These technologies streamline operations, enhancing efficiency and productivity. Automated guided vehicles (AGVs) are increasingly used in warehouses. They navigate independently, delivering goods from one location to another. This reduces manual labor and minimizes human error. However, integrating these systems can present challenges.

Robotics in material handling also includes robotic arms and autonomous drones. These machines can sort, stack, and move items with precision. They work alongside human workers, creating a collaborative environment. Still, the transition requires training and adaptation. Workers may feel uncertain about their roles as machines take on more tasks. Maintenance of robotic systems can demand additional skills from the workforce.

Investing in automation technology comes with risks. Initial costs can be high, and ROI is not always immediate. Not every facility can implement these advanced systems seamlessly. Companies must assess their unique needs before proceeding. The balance between human and machine is crucial. This evolution holds great potential but also requires careful reflection and planning.

The material handling industry is experiencing a significant shift toward sustainability. Reports show that over 70% of companies plan to invest in sustainable materials and technologies in the next few years. This reflects a broader awareness of environmental impacts and a push for greener practices. However, not all organizations are making substantial progress. Many still rely on outdated methods, failing to adopt innovative processes that could drive efficiency.

Recycling and circular economy principles are becoming central to material handling innovations. A recent study stated that implementing these strategies can reduce operational costs by up to 30%. Yet, a lack of understanding and resources often limits their adoption. Training employees on sustainable practices is essential. Organizations that have invested in workforce development often see improved performance and morale.

Automation is also a double-edged sword in sustainability. While it can decrease waste and increase efficiency, the initial setup can be daunting. Current data indicates that only 40% of firms have automated their material handling processes fully. Integrating smart technologies will require ongoing support, both technically and financially. The journey toward sustainability is complex and full of challenges, but it offers significant opportunities for those willing to adapt.

Data analytics and the Internet of Things (IoT) are revolutionizing supply chains. A report by McKinsey reveals that companies using advanced analytics in logistics can improve their operational efficiency by up to 30%. This enhancement leads to a more streamlined flow of goods. Yet, many companies still lag behind in implementing these technologies effectively.

IoT devices collect real-time data from various points in the supply chain. This data can predict demand and monitor inventory levels. A survey from Gartner indicates that 60% of firms utilizing IoT have seen significant improvements in their operational performance. However, integrating these systems poses challenges, such as high initial costs and the need for specialized skills.

Companies must also be aware of data security. With more devices connected, the risk of cyberattacks increases. Organizations should invest in cybersecurity solutions alongside data analytics and IoT strategies. Relying solely on technology without addressing security can lead to severe disruptions. The balance between embracing innovation and ensuring security remains a critical concern for many in the industry.

The landscape of material handling is changing rapidly. As businesses adapt to new technologies, the workforce must also evolve. Skills and training are now more vital than ever. Companies need workers who can operate advanced machinery, understand automation, and interpret data effectively.

Training programs must be tailored to meet these challenges. Traditional methods might not suffice. Upskilling in robotics, data analysis, and safety protocols is essential. Workshops and hands-on training can help bridge skill gaps. However, not all training is effective. Constant feedback and improvement are crucial to ensure the workforce is truly prepared.

Additionally, the adoption of new technologies creates a sense of unease. Many employees fear they may be replaced by machines. Addressing these concerns is part of workforce adaptation. Clear communication and support can alleviate anxiety about job security. Empowering workers with the right tools and knowledge will enhance confidence. In this evolving environment, continuous learning is key.

| Trend | Description | Impact on Workforce | Required Skills | Training Focus |

|---|---|---|---|---|

| Automation Implementation | Increased use of robotics and automated systems for handling materials. | Shift in workforce roles towards monitoring and maintaining automated systems. | Robotics, IT skills, troubleshooting. | Technical training and certification programs. |

| Data Analytics | Utilization of big data to optimize material handling processes. | Need for data-driven decision making and enhanced analytical skills. | Statistical analysis, software proficiency. | Workshops on data interpretation and software tools. |

| Sustainability Practices | Implementation of eco-friendly materials and practices in handling processes. | Awareness and adaptation to new sustainable practices will be essential. | Knowledge of sustainable technologies, waste management. | Training in green practices and compliance regulations. |

| Collaborative Robots (Cobots) | Working alongside human workers to improve efficiency. | Greater focus on teamwork and interaction between humans and machines. | Collaboration, adaptability, operating protocols. | Training on co-working strategies and co-bot operations. |

| Augmented Reality (AR) Training | Using AR for real-time training and assistance in handling tasks. | Enhanced learning experiences for new and existing employees. | Tech-savvy, adaptability, critical thinking. | Interactive training modules that leverage AR technologies. |