- sale@instructrobot.com

- Dallas, TX , United States

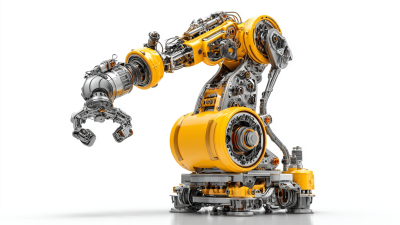

In recent years, the integration of automation in manufacturing processes has witnessed an unprecedented surge, with pick and place robots leading the charge. According to a report by the International Federation of Robotics, the global market for industrial robots is projected to reach $42 billion by 2025, with pick and place robots accounting for a significant portion of this growth due to their ability to streamline operations and enhance productivity. These robots, designed specifically for tasks involving the precise picking, moving, and placing of items, have revolutionized supply chains across various industries, from electronics to food processing.

Industry expert Dr. Emily Chen, a leading figure in robotic automation research, emphasizes the transformative impact of pick and place robots, stating, "The increasing complexity of modern manufacturing demands agile and efficient solutions, and pick and place robots provide exactly that." As businesses strive to meet rising consumer expectations and navigate labor shortages, the adoption of pick and place robots has become essential. They not only reduce labor costs but also improve accuracy and speed in production lines, making them a vital asset for manufacturers aiming to stay competitive in a rapidly evolving market.

In this overview, we will explore the top ten advantages that pick and place robots offer in modern manufacturing, highlighting their contributions to efficiency, safety, and operational excellence.

The integration of pick and place robots into modern manufacturing systems brings a remarkable boost in production line efficiency. These robots are designed to handle repetitive tasks with precision and speed, significantly reducing cycle times. This acceleration in processes allows manufacturers to increase their output without compromising quality. As a result, production lines can operate at optimal capacity, fulfilling larger orders in shorter periods. The automation of these tasks also minimizes human error, which can lead to defects and rework, thereby enhancing overall operational efficiency.

Furthermore, pick and place robots contribute to a more streamlined workflow in manufacturing environments. By automating the movement of products and components, these robots reduce the need for manual labor in routine sorting and packaging tasks. This not only frees up human workers to focus on more complex and value-added activities but also enhances safety in the workplace by minimizing the risks associated with repetitive strain injuries. Additionally, the consistent performance of robots ensures that production lines maintain high levels of throughput, leading to better resource allocation and reduced downtime. The result is a manufacturing process that is not only faster but also more reliable, shaping the future of industrial productivity.

In the rapidly evolving landscape of modern manufacturing, the implementation of pick and place robots is significantly transforming operational efficiencies. One of the primary advantages of these automated systems is their ability to dramatically reduce labor costs. By automating repetitive tasks such as picking, sorting, and placing items, manufacturers can minimize the reliance on human labor for these functions, leading to a leaner workforce. This shift not only cuts expenses associated with salaries and benefits but also enhances productivity by allowing human employees to concentrate on more value-added tasks that require problem-solving and creativity.

Moreover, the reduction in labor costs through automation contributes to consistent output quality and increased production speeds. With robots executing tasks with precision and reliability, the likelihood of errors diminishes, resulting in lower waste and improved efficiency. Additionally, the ability of robots to operate continuously without fatigue means that production lines can maintain optimal performance around the clock. This capability further amplifies cost savings over time, reinforcing the financial viability of adopting pick and place robots in manufacturing facilities. Overall, the strategic integration of these technologies stands as a cornerstone for modern manufacturing, paving the way for smarter, more efficient production processes.

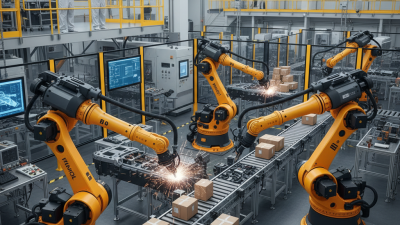

The integration of pick and place robots in modern manufacturing has revolutionized production lines, particularly in enhancing precision and quality control. According to a report by the International Federation of Robotics, the use of industrial robots has led to a drastic reduction in product defects, with error rates dropping by up to 90% in automated assembly processes. This remarkable level of accuracy is crucial for industries where minute details can make a significant difference, such as electronics, automotive, and pharmaceuticals.

Furthermore, the application of advanced robotics technology allows manufacturers to maintain consistent quality throughout production cycles. A study conducted by Deloitte highlights that companies leveraging robotics in their manufacturing processes experience a 20% increase in operational efficiency. This efficiency stems from the robots' ability to perform repetitive tasks with unwavering precision, thereby ensuring that each product meets stringent quality standards. As manufacturers continue to explore automation, the role of pick and place robots in achieving superior quality control and operational excellence is becoming increasingly vital.

In today’s fast-evolving manufacturing landscape, scalability and flexibility have become paramount. Pick and place robots provide manufacturers with the ability to quickly adapt production lines to meet shifting demands, facilitating a rapid response to changes in market requirements. According to a report by the International Federation of Robotics, the integration of these robotic systems can enhance production efficiency by up to 30%, allowing businesses to scale operations without a significant increase in costs or complexity.

Moreover, the modular nature of pick and place systems ensures that manufacturers can easily reconfigure and optimize their setups. A study published by the Association for Advancing Automation suggests that manufacturers utilizing flexible automation can experience a reduction in lead times by as much as 50%. This adaptability not only enhances operational efficiency but also supports the implementation of just-in-time production strategies, helping to minimize inventory costs and improve overall supply chain agility. With the ability to handle various tasks, pick and place robots empower manufacturers to respond dynamically to both production needs and customer preferences, positioning them for sustained competitiveness in the market.

| Advantage | Description | Impact on Production | Example Application |

|---|---|---|---|

| Increased Efficiency | Robots can operate continuously without breaks. | Higher throughput and reduced cycle time. | Automated assembly lines. |

| Precision and Accuracy | Robots perform tasks with high repeatability. | Reduction in defects and waste. | Electronics assembly. |

| Flexibility | Easy to reprogram and adapt to new products. | Quick changeover for different product lines. | Custom packaging solutions. |

| Improved Safety | Reduces human exposure to hazardous tasks. | Safer working environment for employees. | Heavy lifting and hazardous material handling. |

| Cost Savings | Reduction in labor costs and material waste. | Improved profit margins through efficiency. | High-volume production runs. |

| Scalability | Easy to add additional robots as demand increases. | Adaptable to changes in production volume. | Adjusting to market demands. |

| Data Collection | Robots can gather performance data for analysis. | Informed decision-making for process improvements. | Real-time monitoring systems. |

| Consistency | Uniform quality of finished products. | Enhanced brand reputation and customer satisfaction. | High-quality consumer goods. |

| Integration with AI | Enhanced capabilities through machine learning. | Improved decision-making and error reduction. | Smart manufacturing systems. |

| Environmentally Friendly | Optimizes resource use and reduces waste. | Lower carbon footprint in production. | Sustainable manufacturing practices. |

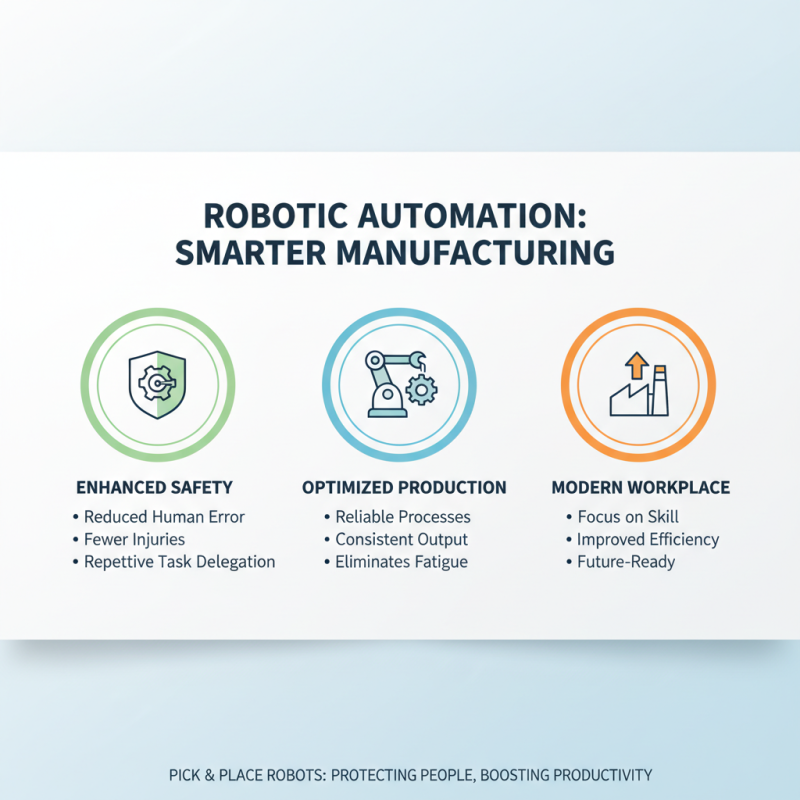

Incorporating pick and place robots into modern manufacturing processes significantly enhances workplace safety by reducing the risk of human error and minimizing injuries. These robots can undertake repetitive and physically demanding tasks, such as lifting heavy objects or assembling components, which are often prone to accidents when performed by human workers. By delegating these tasks to machines, companies not only protect their workforce but also ensure a more reliable production line devoid of the inconsistencies that human fatigue can introduce.

When implementing pick and place robots, consider these tips to maximize safety benefits: first, ensure that all safety protocols are in place and that employees are trained in both robot operation and safety procedures. Regular maintenance and monitoring of robotic systems can further decrease the likelihood of malfunctions that might lead to safety risks. Additionally, involve employees in the transition process to foster an environment of collaboration, making them feel more secure about working alongside advanced technology.

Furthermore, automation can create a more ergonomic workplace. With robots managing heavy lifting, employees can focus on more skilled tasks that require human cognitive abilities, ultimately reducing workplace strain and the incidence of musculoskeletal disorders. Ensuring a well-designed interaction between human and robotic systems can lead to a smoother operation and a safer work environment for all.