- sale@instructrobot.com

- Dallas, TX , United States

In the ever-evolving landscape of manufacturing and logistics, the adoption of automation technologies has become crucial for enhancing efficiency and productivity. Among these advancements, the FANUC palletizing robot stands out as a game-changer for businesses aiming to optimize their operations. John Smith, an industry expert in robotic automation, emphasizes this point by stating, "The integration of FANUC palletizing robots not only streamlines processes but also reduces labor costs and enhances precision in product handling."

The benefits of utilizing FANUC palletizing robots extend beyond mere operational enhancements; they also contribute significantly to overall workplace safety and employee satisfaction. As companies strive to meet increasing production demands, the ability to deploy advanced robotic solutions has proven indispensable. By leveraging the capabilities of FANUC palletizing robots, businesses can achieve a competitive edge in today's fast-paced market while ensuring that their human workforce can focus on more strategic tasks.

In the following sections, we will delve into the top ten benefits of incorporating FANUC palletizing robots into your business model, illustrating how these technological innovations are not just an investment in machinery, but a commitment to the future of efficient and sustainable operations.

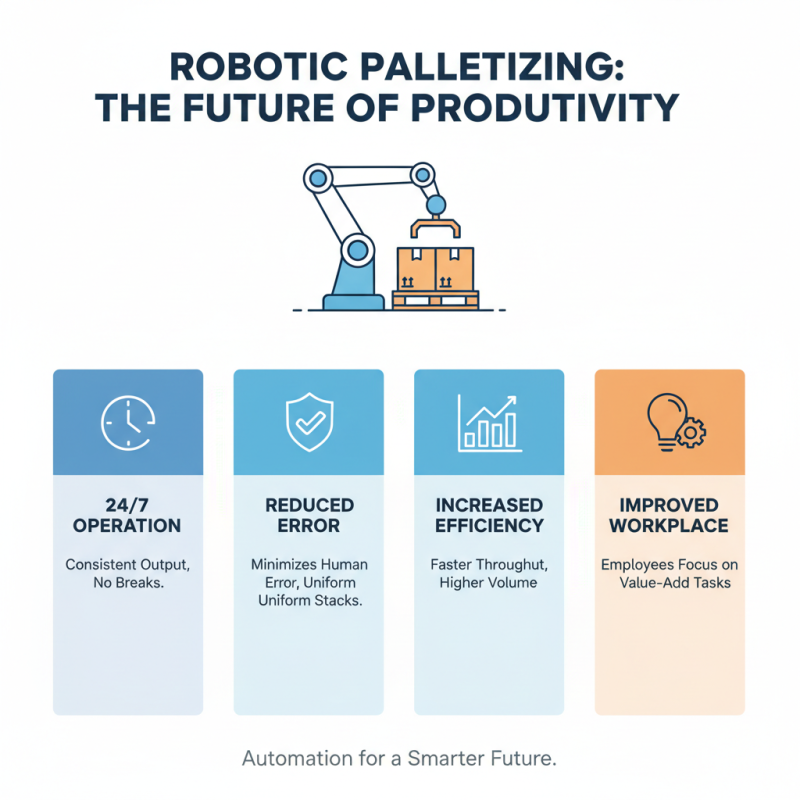

Automation has revolutionized various industries, and the integration of palletizing robots is one of its most beneficial advancements. By adopting robotic palletizing systems, businesses gain a significant edge in efficiency and productivity. These robots can operate around the clock, reducing the need for breaks and minimizing human error. This allows for a consistent output rate, ensuring that production goals are met without the fluctuations that come with manual labor. Additionally, automating repetitive tasks enhances the workplace environment, allowing employees to focus on more complex and value-added activities.

Another key advantage of utilizing palletizing robots is the reduction in workplace injuries. Manual palletizing can be physically demanding, often leading to strain and injuries among workers. With robots taking on these heavy lifting and repetitive tasks, companies not only safeguard their workforce but also lower healthcare costs and enhance overall worker satisfaction. Furthermore, the precision offered by robotic systems leads to better product handling, reducing damage during the packing process. This not only preserves product integrity but also improves customer satisfaction through timely and accurate deliveries.

The integration of palletizing robots into material handling systems is revolutionizing efficiency for businesses across various industries. These advanced robotic systems enhance productivity by automating repetitive tasks such as stacking and organizing products. According to a report by the International Federation of Robotics, the global sales of industrial robots, including palletizing systems, have grown by approximately 30% year-over-year, indicating a strong trend towards automation in manufacturing processes. With robots capable of operating 24/7, companies can significantly reduce downtime and optimize workflow, ultimately boosting output.

Incorporating palletizing robots leads to a more streamlined operation, significantly reducing human error and improving accuracy in product handling. Research from the Robotics Industries Association shows that automation can decrease labor costs by up to 40%, making it an economically viable option for many businesses. As organizations invest in robotic solutions, they also experience an improvement in employee safety, as robots can take over dangerous tasks, allowing human workers to focus on higher-value activities.

Tip: When implementing palletizing robots, ensure that your material handling systems are compatible with the new technology. Conduct a thorough assessment of your existing processes to identify integration points that can maximize the benefits of automation. Additionally, consider ongoing training for your workforce to effectively operate and maintain these advanced systems, further enhancing overall efficiency.

In today's competitive business landscape, minimizing operational costs is a primary concern for many companies. One significant area where savings can be achieved is through the implementation of automation in manufacturing processes. Utilizing palletizing robots can lead to remarkable reductions in labor costs. These machines can perform tasks that would typically require multiple human workers, effectively streamlining operations and reducing the overhead associated with hiring, training, and maintaining a workforce.

Moreover, the operational efficiency gained from robot automation cannot be underestimated. Unlike human labor, which is subject to fatigue and errors, palletizing robots operate with precision and consistency, significantly reducing the risk of product damage and errors in packaging. Companies can experience lower material costs due to fewer mistakes, ensuring that products are delivered in optimal condition. The combination of reduced labor expenses and enhanced operational effectiveness creates a compelling case for businesses looking to improve their bottom line through automation solutions.

In today’s fast-paced manufacturing landscape, having a flexible and scalable production line is essential for staying competitive. The integration of palletizing robots into your operations can significantly enhance flexibility. These robots are designed to adapt to various product sizes and configurations, allowing businesses to switch between different tasks with minimal downtime. This adaptability means that whether you’re handling bags, boxes, or irregularly shaped items, your production line can accommodate changing demands effortlessly.

To optimize the scalability of your production processes, consider modular robotic solutions that can grow alongside your business needs. These robots can be easily added to existing setups, enabling you to scale operations smoothly as demand fluctuates. Investing in this technology not only future-proofs your production line but also improves overall efficiency, helping to reduce labor costs and minimize errors.

Tip: Regularly assess your production volume and product variety to ensure your robotic systems are aligned with your operational goals. Also, keep an eye on advancements in robotic technology that could provide additional features or enhance the performance of your current system. This proactive approach will ensure you remain at the forefront of operational effectiveness.

This chart illustrates the top 10 benefits of implementing Fanuc palletizing robots in production lines, showcasing improved flexibility and scalability.

In the competitive landscape of modern manufacturing, the integration of robotics, particularly in palletizing tasks, has shown remarkable advancements in precision and consistency.

According to a report by the International Federation of Robotics, manufacturers that utilize robotic palletizers witness an increase in operational efficiency of up to 30%.

This enhancement allows businesses to not only streamline their processes but also significantly reduce the incidence of product damage associated with manual handling.

The inherent accuracy of robotic systems minimizes the risk of misaligned or improperly stacked pallets, which can lead to costly setbacks in logistics and shipping.

Data from the Robotics Industry Association indicates that the implementation of automated palletizing solutions can improve the accuracy of pallet stacking by 85%.

This precision is crucial for maintaining the integrity of products throughout the supply chain, ensuring that goods arrive at their destinations in optimal condition.

Furthermore, consistent performance in palletizing tasks contributes to better inventory control and reduced labor costs, reinforcing the argument for automating this critical component of production operations.

The inherent accuracy of robotic systems minimizes the risk of misaligned or improperly stacked pallets, which can lead to costly setbacks in logistics and shipping.

Data from the Robotics Industry Association indicates that the implementation of automated palletizing solutions can improve the accuracy of pallet stacking by 85%.

This precision is crucial for maintaining the integrity of products throughout the supply chain, ensuring that goods arrive at their destinations in optimal condition.

Furthermore, consistent performance in palletizing tasks contributes to better inventory control and reduced labor costs, reinforcing the argument for automating this critical component of production operations.