- sale@instructrobot.com

- Dallas, TX , United States

The industrial landscape is evolving rapidly, with companies seeking efficiency and innovation. The use of robots has surged in recent years. According to a report by the International Federation of Robotics, global sales of industrial robots reached 384,000 units in 2022 alone. Among them, used robots are increasingly becoming a viable option for businesses. They offer significant cost savings while maintaining functionality and reliability.

Used robots can help companies reduce upfront costs. Many organizations are now recognizing their potential in boosting productivity. A recent study by Deloitte found that 74% of manufacturers consider automation critical for staying competitive. However, the transition to used robots is not without its challenges. Companies often face concerns regarding compatibility and integration with existing systems. Proper assessment of the robot's history and performance is crucial.

Despite these potential pitfalls, the benefits of adopting used robots are compelling. They often come with a solid track record and proven results. Companies must weigh the advantages against the risks. A measured approach can lead to better outcomes, maximizing production while minimizing expenditure. As industries continue to embrace automation, the role of used robots cannot be overlooked.

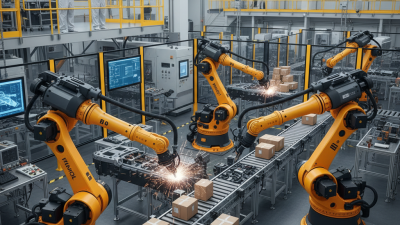

The landscape of industrial applications is rapidly evolving with the use of robots. In 2026, we see a variety of used robots enhancing efficiency. They are being adopted across sectors like manufacturing, logistics, and agriculture. Many factories now employ robotic arms for assembly tasks. These robots can work tirelessly, allowing human workers to focus on complex roles.

However, the integration of used robots comes with challenges. Not all machines are efficient. Their performance can vary, and some might require repairs. Companies must consider the costs of maintaining older models. Training staff to interact with these robots is essential. In certain cases, the learning curve can be steep.

The decision to invest in used robots isn't straightforward. Businesses need to analyze their specific needs first. Choosing the right robot model can significantly affect overall productivity. Many companies are realizing that not every robot fits every task. Continuous assessments and adjustments may be necessary as technology advances. The future is promising, but it requires careful navigation.

When choosing robots for efficiency, several key features are essential to consider. First, assess the robot’s payload capacity. This determines how much weight it can handle. A robot with a higher capacity is often more versatile in various tasks.

Next, think about precision and repeatability. Robots that can consistently perform tasks with high accuracy minimize errors. In industries like manufacturing, this reduces waste. Flexibility is also important. A robot that can easily adapt to different tasks increases its value.

Tips: Evaluate the ease of programming. User-friendly interfaces make it simpler for operators. Look for models that integrate easily with existing systems. This can save time and resources during implementation.

Consider longevity and maintenance needs. Durable robots may save costs over time. Check how often parts need replacement. Some robots may require more frequent servicing. Think about the available support and resources too. If issues arise, quick assistance is crucial for keeping operations running smoothly.

| Robot Type | Key Features | Typical Applications | Efficiency Rating | Price Range |

|---|---|---|---|---|

| Collaborative Robots (Cobots) | User-friendly interface, safety sensors | Assembly, packaging, and materials handling | High | $20,000 - $45,000 |

| Automated Guided Vehicles (AGVs) | Navigation systems, load capacity | Material transport, warehouse logistics | Moderate | $30,000 - $80,000 |

| Industrial Robots | High precision, payload versatility | Welding, painting, and assembly lines | Very High | $50,000 - $150,000 |

| Service Robots | AI integration, mobile capabilities | Customer service, cleaning, and security | High | $15,000 - $60,000 |

| Drones | Aerial surveillance, delivery systems | Inventory management, agriculture, mapping | Moderate | $1,000 - $20,000 |

The manufacturing sector is rapidly embracing automation through used robots. According to a report by the International Federation of Robotics, global robot installations surged by 12% in 2022, underscoring the industry's thirst for efficiency. Used robots provide a cost-effective path for manufacturers seeking to modernize. They offer reliability without the hefty price tag of new models.

In some factories, automation can decrease downtime by nearly 30%. However, integrating used robots poses challenges. Companies must assess each robot's condition. Compatibility with existing systems is crucial, often requiring additional investments. Many firms underestimate the importance of training their workforce to work alongside these machines. A lack of training can lead to inefficiencies that counteract the benefits of automation.

Flexibility is another critical factor. Some industries may require specialized robotic solutions that used robots can't always fulfill. A 2021 McKinsey report highlighted that 40% of tasks in manufacturing could be automated. Yet, many sectors still struggle to implement these technologies effectively. Investing in used robots can sometimes be a gamble. Organizations must weigh the immediate cost savings against long-term operational needs.

Used robots are transforming industries worldwide. In manufacturing, robots increase output and reduce costs. One case study highlights a furniture factory that implemented used robotic arms. They streamlined assembly lines, cutting labor costs by 20%. Shifts became more efficient, but initial programming errors delayed production.

In agriculture, another example showcases used robots in harvesting. A farm adopted robotic equipment to gather crops. This reduced the need for seasonal workers. However, the robots often struggled with uneven terrain. Agility issues resulted in inconsistent harvesting times. While the solution is effective, continuous adjustments are necessary.

Logistics companies are also benefiting from used robots. Automated guided vehicles transport goods between warehouses with remarkable speed. In one instance, an online retailer saved significantly on shipping times. Yet, integration with existing systems posed challenges. Proper training for staff was essential but overlooked initially.

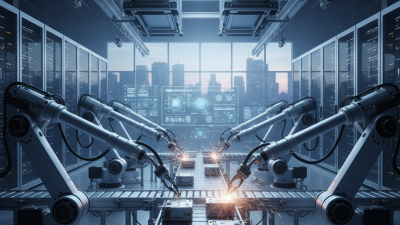

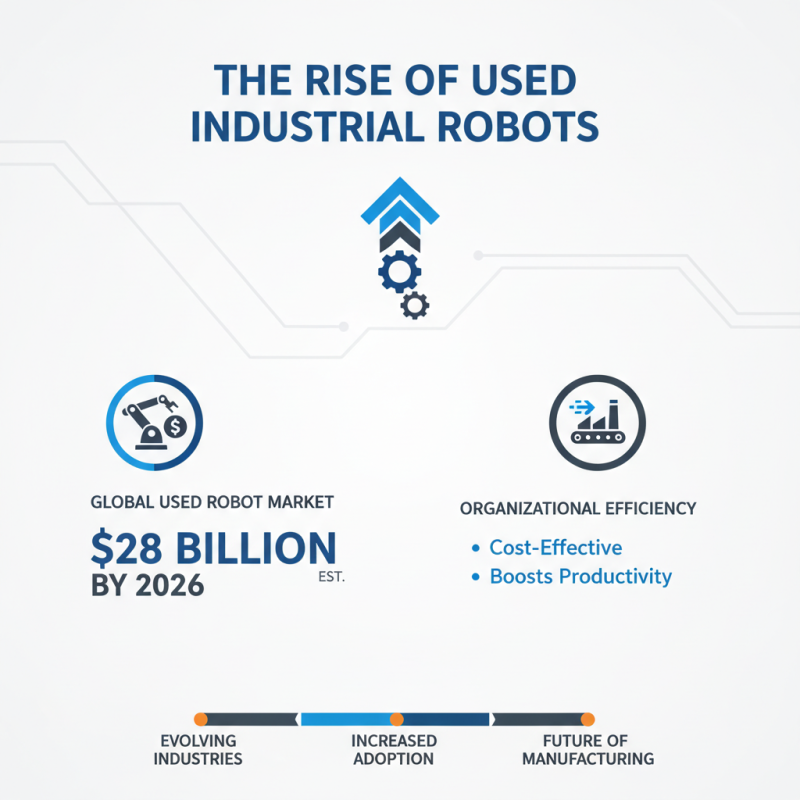

As industries evolve, the use of robots continues to rise. A recent report indicates that the global market for used industrial robots will reach $28 billion by 2026. Organizations are increasingly turning toward efficiency. Used robots are a cost-effective option for businesses looking to enhance productivity.

The adoption of used robots impacts efficiency significantly. A study found that companies using automation saw a 20% increase in output. However, not all robots deliver the expected results. Choosing the right model remains a challenge. Some robots can struggle with specific tasks. The integration process is often complicated. Companies must invest time and resources to train employees on new systems.

The future trends show a shift towards intelligent automation. Design flexibility and modular capabilities are becoming essential. The rise of advanced analytics allows for better monitoring of robot performance. Reports suggest that by 2025, over 75% of organizations will utilize data analytics in their robotic systems. This evolution will lead to improved operational efficiency. Nevertheless, companies need to address potential downtime and maintenance costs. Balancing automation and human labor will require careful consideration. Only then can businesses maximize the potential of used robots effectively.