- sale@instructrobot.com

- Dallas, TX , United States

Choosing the right robot integrator is a critical decision for any organization looking to enhance efficiency and achieve automation goals. The effectiveness of automation systems hinges not only on the technology itself but also on the expertise and reliability of the robot integrator responsible for implementing these solutions. A proficient robot integrator brings valuable knowledge and experience, guiding businesses through the myriad of options available on the market and ensuring that their specific needs are met.

In today’s fast-paced industrial environment, the demand for automation solutions continues to grow, making the selection of a competent robot integrator more important than ever. Each automation project presents unique challenges and requirements, necessitating a tailored approach. By carefully evaluating potential integrators based on their technical skills, industry experience, and past project success, organizations can make informed decisions that align with their operational objectives. This introduction delves into the essential criteria for selecting a robot integrator, empowering businesses to harness the full potential of automation technology effectively.

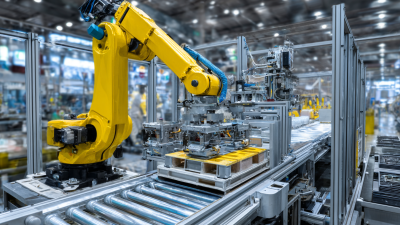

Robot integrators play a crucial role in the landscape of automation solutions, acting as the vital link between robotic systems and the industries that utilize them. Their expertise lies in understanding the specific needs of a business and translating those requirements into effective automation strategies. This involves selecting the right robots, configuring them for particular tasks, and ensuring compatibility with existing systems. The integrator’s role goes beyond mere installation; they are responsible for optimizing the entire automation process to improve efficiency, productivity, and safety.

Furthermore, robot integrators provide essential support throughout the lifecycle of the automation project. This includes not only initial setup but also ongoing maintenance and troubleshooting, ensuring that systems operate smoothly over time. They also offer valuable insights into the latest technological advancements and industry trends, helping businesses stay competitive. By establishing a strong partnership with a qualified integrator, companies can effectively tailor their automation solutions to meet specific goals, ultimately enhancing their operational capabilities and driving innovation within their sectors.

When selecting a robot integrator for your automation needs, it’s crucial to consider several key factors to ensure the right fit for your specific requirements. One of the primary considerations is the integrator's experience and expertise in your industry. Look for a provider who has a proven track record of successful implementations and understands the unique challenges your sector faces. This insight will not only enhance the efficiency of your automation systems but also minimize potential pitfalls during integration.

Another essential factor is the level of customization offered by the robot integrator. Every business is unique, and off-the-shelf solutions may not address your specific needs. Make sure the integrator is willing and capable of tailoring solutions to match your operational goals. This could include modifications in software, hardware, or even the automation strategy itself, ensuring maximum ROI on your investment.

**Tips:** When evaluating potential integrators, request case studies or references that demonstrate their problem-solving capabilities. Additionally, consider their post-implementation support and maintenance services, as ongoing assistance is critical for long-term success and system reliability. Engaging with multiple integrators can provide valuable insights and options, making it easier to find the best partner for your automation journey.

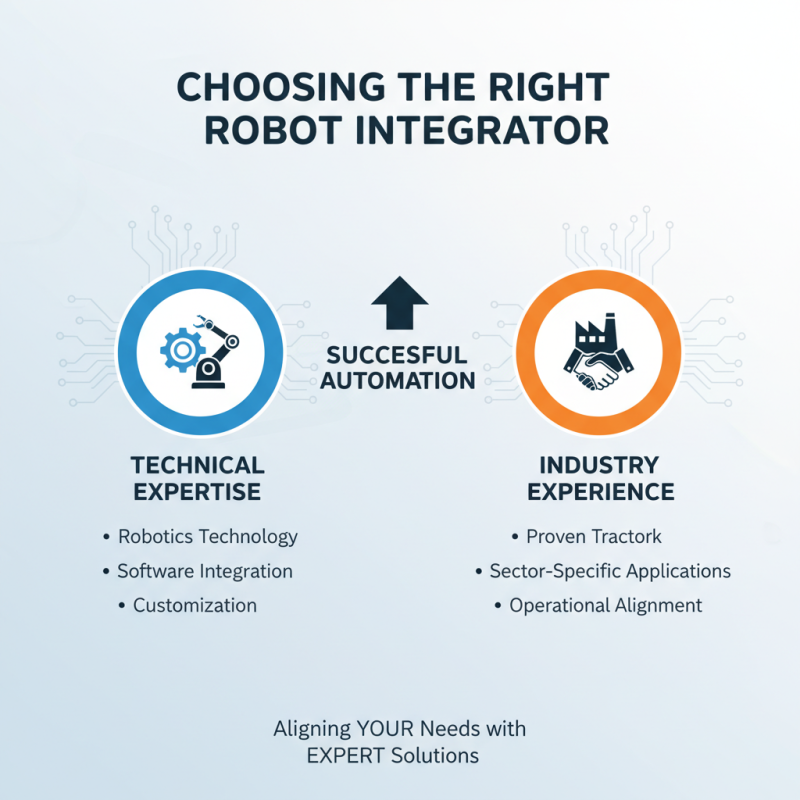

When selecting the right robot integrator for your automation needs, evaluating their technical expertise and industry experience is crucial. A skilled integrator should possess a deep understanding of robotics technology, software integration, and the specific applications relevant to your sector. Look for integrators with a proven track record of successful implementations. They should demonstrate a strong ability to customize solutions based on your unique operational requirements, ensuring that the automation aligns perfectly with your existing processes.

Moreover, industry experience plays a significant role in determining how well an integrator can address your challenges. An integrator with robust experience in your field will be more adept at anticipating potential pitfalls and tailoring solutions accordingly. They should be familiar with the regulatory constraints and best practices specific to your industry. By investing time in assessing an integrator’s past projects and client feedback, you can gauge their capability to deliver effective automation solutions that not only enhance productivity but also integrate seamlessly into your organizational structure.

When selecting a robot integrator for automation projects, evaluating their project management skills and communication capabilities is paramount. According to a report by the Association for Advancing Automation (A3), successful automation implementations hinge on effective communication; as much as 70% of project delays are attributed to misunderstandings between stakeholders. A competent integrator should not only have a strong grasp of technical aspects but also possess the ability to convey complex ideas clearly and ensure all team members are aligned throughout the project lifecycle. This can foster a collaborative working environment that ultimately leads to smoother deployments.

Furthermore, an integrator's project management skills play a critical role in delivering results on time and within budget. The Project Management Institute (PMI) highlights that organizations with effective project management practices see a 28% increase in project success rates. Key indicators of a solid project manager include their ability to set realistic timelines, manage risk proactively, and allocate resources efficiently. By assessing these skills during the selection process, businesses can mitigate potential issues and enhance the overall success of their automation initiatives, ensuring that the integration of robotic systems delivers the intended return on investment.

| Dimension | Criteria | Rating Scale | Example Rating |

|---|---|---|---|

| Project Management Skills | Experience with similar projects | 1-5 scale | 4 |

| Project Management Skills | Ability to meet deadlines | 1-5 scale | 5 |

| Project Management Skills | Resource management | 1-5 scale | 3 |

| Communication | Clarity in communication | 1-5 scale | 4 |

| Communication | Responsiveness | 1-5 scale | 4 |

| Communication | Proactiveness in addressing issues | 1-5 scale | 5 |

When selecting a robot integrator for your automation projects, understanding cost structures and potential Return on Investment (ROI) is crucial. According to a report by the International Federation of Robotics, investing in automation can lead to productivity gains of up to 30% in manufacturing sectors. However, the initial upfront costs of integrating robots can vary significantly based on the complexity of the tasks and the technology involved. A thorough analysis of these cost structures will help identify hidden expenses such as maintenance, training, and software updates, which are essential for calculating true ROI.

To ensure a successful automation initiative, consider the following tips. First, conduct a comprehensive cost-benefit analysis that includes both direct and indirect costs associated with robot integration. This involves not just the purchase price, but also installation and operational costs over time. Second, evaluate the expected lifespan of the robotic systems and their compatibility with existing operations. A well-implemented automation project can yield returns exceeding 200% within a few years, according to industry benchmarks. Engaging with a robot integrator who provides transparent pricing and a clear breakdown of expected returns can make this process seamless.

Another essential factor to evaluate is the flexibility that the integrator offers. As automation needs evolve, your chosen systems should be adaptable to new technologies and operational changes without incurring significant extra costs. According to a report from McKinsey, flexible automation can reduce total cost of ownership by approximately 40%, reinforcing the importance of selecting a capable partner who understands future readiness in automation solutions.