- sale@instructrobot.com

- Dallas, TX , United States

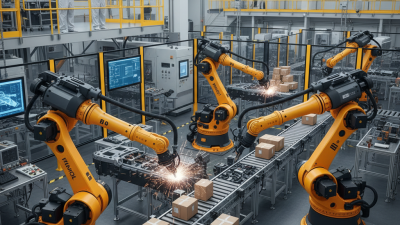

In today's rapidly evolving industrial landscape, the integration of robotic systems has become crucial for companies aiming to enhance their operational efficiency. According to a November 2021 report by the International Federation of Robotics, the global sales volume of industrial robots reached a record high of around 486,000 units, underscoring the increasing reliance on automation across various sectors. However, the successful implementation of robotic solutions often hinges on the expertise and experience of a specialized partner known as a robot integrator.

Choosing the right robot integrator can significantly streamline your operations by ensuring that the robotic systems are seamlessly integrated into existing workflows. As highlighted in a 2022 report by McKinsey & Company, organizations that effectively utilize robot integrators can reduce operational costs by up to 30% and shorten project implementation timelines by 50%. This emphasizes the vital role that skilled integrators play in mitigating risks and enhancing productivity. By leveraging their technical know-how and industry insights, robot integrators empower companies to not only adopt automation but to do so in a way that maximizes return on investment and fosters long-term growth.

In the rapidly evolving landscape of industrial automation, the role of robot integrators has become increasingly vital. These professionals specialize in designing, implementing, and supporting robotic systems that seamlessly integrate into existing workflows. According to a report from MarketsandMarkets, the global industrial robotics market is projected to reach $75.6 billion by 2026, indicating a significant shift toward automation-driven processes. As companies strive to improve efficiency and reduce operational costs, robot integrators provide the expertise needed to navigate complex robotic system implementations.

To maximize the benefits of robotic automation, consider the following tips: First, clearly define your operational challenges. This allows the robot integrator to tailor solutions that align with your specific needs. Additionally, ensure that you establish open communication channels throughout the integration process. A study from McKinsey highlights that companies with effective communication experience 30% more project success rates. Finally, prioritize training for your staff post-integration, as this will empower them to work effectively with new technologies and enhance overall productivity.

As industries continue to adopt advanced automation technologies, a robust partnership with a skilled robot integrator will be a cornerstone for achieving a streamlined operation. This collaboration not only facilitates smoother transitions but also positions businesses to adapt swiftly to market changes, ultimately driving sustained growth and innovation in an increasingly competitive environment.

Collaborating with a robot integrator has become a crucial strategy for companies aiming to enhance operational efficiency, particularly in the rapidly growing automotive robotics market. As the global market is projected to reach $9.92 billion in 2024, with an anticipated growth to $11.21 billion in 2025 and soaring to $26.76 billion by 2032, the importance of streamlined operations cannot be overstated. Robot integrators bring a wealth of expertise, helping businesses integrate robotic solutions seamlessly into their existing workflows.

One of the key benefits of working with a robot integrator is the significant reduction in downtime. By developing tailored automation solutions, integrators ensure that machinery and processes operate smoothly and efficiently, minimizing interruptions. Furthermore, their deep understanding of robotic systems allows them to offer insights into best practices and innovative technologies that enhance production capabilities. This partnership not only leads to cost savings but also fosters adaptability, enabling organizations to respond effectively to changing market demands while maintaining high efficiency levels.

When selecting a robot integrator, understanding your specific needs is paramount. Begin by identifying the areas in your operations that require automation and the types of tasks you want the robots to perform. This clarity will help you communicate effectively with potential integrators, ensuring they have the expertise and solutions that align with your operational goals.

**Tips**: Conduct a thorough evaluation of the integrator's past projects and case studies that are similar to your industry. Look for customer testimonials to gauge their reliability and service quality. Engage in discussions with the integrator's team to assess their technical capabilities, including their adaptability and problem-solving skills in real-world applications.

Another critical aspect is the integrator’s support and maintenance offerings. A good robot integrator doesn’t just set up the system and walk away; they provide continuous support and upgrades as needed. Make sure to inquire about their training programs for your employees, ensuring that your team can effectively operate and troubleshoot the robotic systems.

**Tips**: Ask for detailed support plans and response times in case of system failures. Consider whether they offer remote support, which can significantly reduce downtime.

This bar chart illustrates the average time spent on different phases of robot integration projects. It highlights the importance of choosing a competent robot integrator, as it can significantly streamline the integration process and reduce total deployment time.

Integrating robotics into existing operations is a strategic move that can significantly enhance efficiency, particularly for brownfield manufacturing environments. As businesses modernize their facilities, leveraging autonomous mobile robots (AMRs) can bridge the gap between outdated systems and new technologies. These robots are designed to adapt to legacy setups, enabling manufacturers to improve workflows and productivity without the need for complete system overhauls. Successful integration hinges on understanding the unique challenges of brownfield environments and selecting the right robot integrator who can navigate these complexities.

In the hospitality industry, robotic process automation (RPA) is also gaining traction, driven by critical success factors such as leadership commitment, employee engagement, and robust training programs. Hotels are increasingly incorporating robots that can enhance guest experiences by providing services without the traditional limitations of human staff. This transition not only streamlines operations but also allows human employees to focus on value-added tasks. Ultimately, a thoughtful approach to integrating robotics, guided by experienced robot integrators, is vital for unlocking the full potential of automation across various sectors.

| Integration Strategy | Benefit | Potential Challenges | Recommended Practices |

|---|---|---|---|

| Conducting a Needs Assessment | Identifies areas for improvement | Incomplete information gathering | Involve multiple stakeholders |

| Choosing the Right Technology | Enhances operational efficiency | Misalignment with existing systems | Research current market solutions |

| Pilot Testing | Validates effectiveness before full deployment | Limited scope of testing | Include diverse scenarios in tests |

| Training Staff | Ensures smooth transition to new processes | Resistance to change | Incorporate hands-on learning |

| Continuous Improvement | Optimizes long-term operations | Underestimating the need for updates | Regularly analyze performance metrics |

In the rapidly evolving landscape of automation, partnering with a robot integrator can significantly enhance your return on investment (ROI). According to a report by the International Federation of Robotics, companies that implement robotic solutions can see productivity increases of up to 30% within the first year. This not only boosts efficiency but also results in substantial long-term cost savings, making the initial investment in robot integration worthwhile.

One effective tip is to assess your operational needs before engaging with a robot integrator. By clearly defining your goals, you can ensure that the integration process aligns perfectly with your business objectives. Additionally, consider the scalability of the solutions offered; as your business evolves, your robotic systems should be able to adapt accordingly.

Another crucial aspect is to evaluate the long-term support and maintenance services provided by the integrator. A study from McKinsey & Company revealed that 75% of organizations report higher success rates when implementing technology solutions that include robust support systems. Ensuring that you have reliable ongoing assistance can maximize the longevity and performance of your robotic systems, ultimately enhancing your ROI even further.