- sale@instructrobot.com

- Dallas, TX , United States

Choosing the right fanuc palletizing robot is crucial for your business. Industry expert John Smith once stated, “The right robot can enhance efficiency and reduce costs.” His insight highlights the significance of tailored solutions in automation.

When assessing a fanuc palletizing robot, consider your specific needs. Factors like payload capacity, reach, and speed matter. Each business will have unique requirements. For instance, a lightweight product may need a different robot than heavy machinery parts.

Understanding these details can be challenging. You might feel overwhelmed by options. However, clarity will lead to better decisions. Remember, investing in a fanuc palletizing robot is a step toward greater productivity and efficiency. Balancing cost and performance is key to a successful choice.

Choosing the right palletizing robot is crucial for boosting efficiency. Several factors influence this decision. One key factor is payload capacity. Many businesses report that robots with higher payloads can handle a wider range of products. According to a recent industry study, 60% of companies found increased productivity with robots that manage heavier loads.

Another essential factor is the robot's speed. Faster operations can significantly reduce cycle times. A survey indicated that companies utilizing high-speed robots improved throughput by nearly 30%. Ensure the robot matches your production rate.

Tip: Assess your current and future needs. Investing in a robot with scalable features can save costs in the long run.

Consider the robot's ease of programming and integration. Some systems may require extensive training. A complex setup could lead to downtime and frustration. A study revealed that 40% of users faced integration challenges when adopting new robotic systems.

Tip: Seek out user-friendly robotic solutions. They can alleviate the learning curve and enhance overall efficiency.

By focusing on these key factors, your organization can select the best palletizing robot tailored to your needs, driving productivity while minimizing complications.

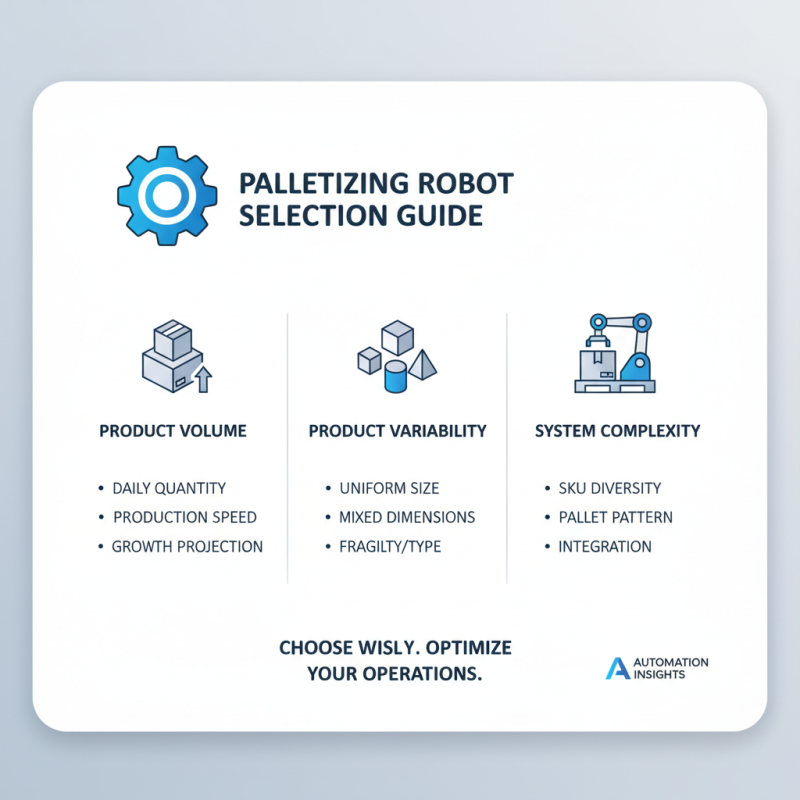

Understanding the specific palletizing needs of your business is crucial. Start by assessing the volume of products you handle daily. Are they uniform in size? Or do you deal with varying dimensions? The complexity of your product lineup will significantly influence your robot choice. A few unique items can lead to challenges during the palletizing process.

Consider the layout of your workspace too. Is there ample room for the robot's movement? Limited space may restrict options. Also, think about the types of pallets you use. Different designs require different handling techniques. Understanding these needs can help refine your search.

Reflect on your future growth as well. Will you expand your product line or increase production pace? Sometimes, an initial choice may not cater to long-term goals. Knowing how your business may evolve will inform your decision. Every detail influences the best robotic solution for your requirements. Stay critical and aware of these aspects for effective palletizing solutions.

When selecting a palletizing robot, evaluating payload capacity and reach is crucial. Payload capacity refers to the maximum weight a robot can handle effectively. Many businesses overlook this aspect. A robot that cannot handle your heaviest products may lead to inefficiencies and complications in the long run. Assess your heaviest items and choose a robot that comfortably exceeds this weight. This prevents potential breakdowns and ensures smooth operations.

Reach is another critical factor. It determines how far the robot can extend its arm. A robot with insufficient reach may struggle to access certain areas of your workspace. This can cause delays and impact productivity. Visualize your production layout. Identify any restricted spaces that the robot must navigate. Adjust your choices accordingly to ensure optimal performance in your setting.

It’s essential to recognize that sometimes, the best specifications do not guarantee reliability. A robot may have impressive numbers but might not fit your specific needs. Engage with team members to gather insights. Consider the operational environment during assessments. This reflection can enhance your selection process and contribute to better decision-making.

| Robot Model | Payload Capacity (kg) | Reach (mm) | Application Type | Special Features |

|---|---|---|---|---|

| Model A | 70 | 1400 | Food Industry | Compact design, high speed |

| Model B | 100 | 1600 | Beverage Industry | Flexible configuration, high precision |

| Model C | 150 | 1800 | Consumer Goods | High throughput, user-friendly |

| Model D | 200 | 2000 | Pharmaceuticals | Cleanroom capable, customizable tooling |

When selecting a palletizing robot, software compatibility is essential. A robust software suite can enhance operational efficiency. Research indicates that 70% of companies experience downtime due to integration issues. This cost can significantly impact productivity. A seamless connection between the robot and existing systems ensures smoother workflows.

Consider the types of control software available. Many robots require specific programming languages or platforms. A report from a leading industry analyst states that 65% of users find integration with legacy systems challenging. It's crucial to evaluate the skill set of your team. If your staff lacks familiarity with certain software, it could lead to delays. Training programs can mitigate this, but they require time and investment.

Documentation also plays a key role in integration. Clear, concise manuals can reduce implementation times. Yet, sometimes such resources are inadequate. Surveys show that 40% of businesses struggle with incomplete documentation. This gap necessitates a proactive approach in seeking support. A lack of proper resources can lead to costly mistakes. Each step must be diligently planned and executed. Addressing these factors thoughtfully can lead to a more successful integration process.

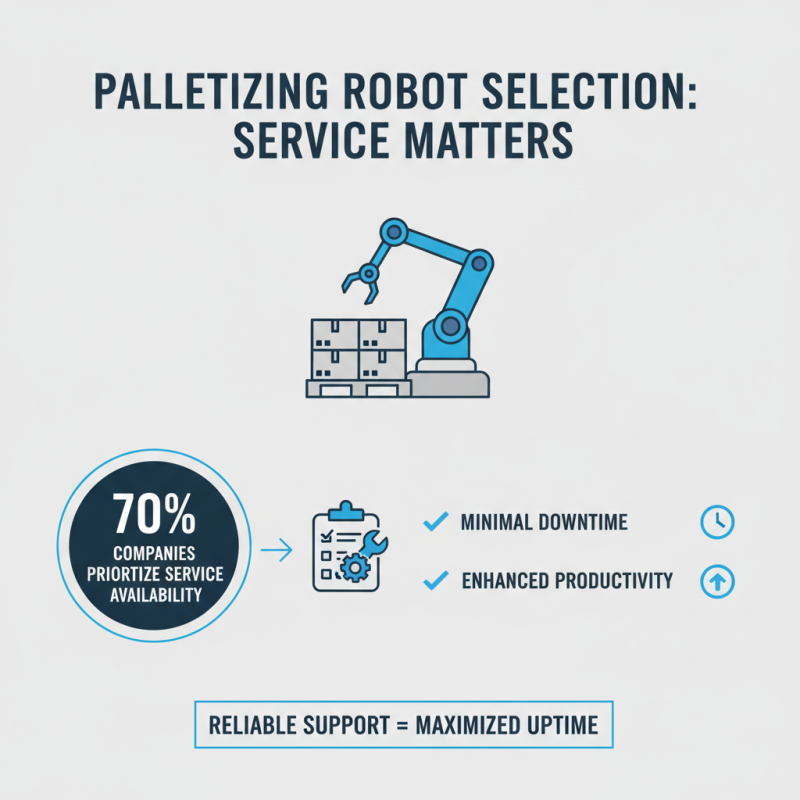

When selecting a palletizing robot, support and maintenance services are crucial. According to a recent industry report, 70% of companies prioritize service availability when choosing robotic solutions. Reliable support ensures minimal downtime and enhances overall productivity.

Maintenance services can vary widely among providers. Regular maintenance checks can prevent unexpected failures. A study found that 60% of robot failures occur due to inadequate upkeep. Investing in service contracts can mitigate these risks. Companies must consider the responsiveness and expertise of the support team.

It's essential to evaluate the long-term costs of support. Some providers offer attractive initial prices but lack comprehensive service plans. Without robust maintenance, users might face high repair bills later. Analyze providers carefully. Understand what each service package includes. This will help avoid pitfalls and ensure a reliable workflow.