- sale@instructrobot.com

- Dallas, TX , United States

In today's fast-paced business environment, adopting robot solutions is becoming crucial. According to a report by McKinsey, automation could contribute up to $6.3 trillion annually to global productivity by 2030. This shift allows companies to streamline operations and enhance efficiency. However, selecting the right robot solutions can be challenging.

Many businesses rush into purchasing robots without analyzing their specific needs. This can lead to wasted resources and underwhelming returns. The International Federation of Robotics states that global robot installations increased by 12% in 2020. Yet, not all companies maximize their investments. Understanding your unique requirements is essential for success.

Some organizations overlook the importance of scalability. A solution that works today may not meet future demands. Lack of foresight can hinder growth. While robot solutions offer numerous benefits, careful consideration is vital. Each business must reflect on their operations, budgets, and long-term goals before finalizing a choice.

Choosing the right robotic solutions begins with a clear understanding of your business needs. What specific tasks do you want to automate? According to a recent industry report, 57% of businesses that implemented robotic solutions saw an increase in efficiency. This statistic underscores the importance of aligning technology with operational goals.

To identify your needs, conduct a thorough analysis of your current workflows. Look for repetitive tasks that consume valuable labor hours. It's important to involve team members from various departments. They can provide insights into pain points that may not be immediately visible. For example, warehouse workers can identify sorting issues that slow down processes.

**Tip:** Start with a pilot project. Test automation on a smaller scale. This approach minimizes risk and reveals unforeseen challenges. Adaptations may be needed, and feedback will be vital.

Next, consider scalability. Your initial choice should be flexible enough to grow with your business. Industry forecasts suggest that the market for robotic solutions will double in the next five years. Businesses that invest wisely now can leverage advanced technologies later.

**Tip:** Keep an eye on technological advancements. What works today might need reevaluation tomorrow. Adaptation is key in a rapidly changing environment. Don't just settle for the first solution that seems fit.

When evaluating different types of robots for specific applications, businesses must consider their unique needs. Industrial robots, for instance, excel in manufacturing tasks. According to a report by the International Federation of Robotics, the global stock of industrial robots reached 3 million units in 2021. This highlights the growing reliance on automation in various sectors. Efficiency is key here, but not every robotic solution is a perfect fit.

Service robots present another avenue. They are increasingly popular in hospitality and healthcare. A study from MarketsandMarkets predicts that the global service robotics market will grow to $23.2 billion by 2026. However, businesses should reflect on whether they truly require these solutions. The initial investment can be significant, and operational costs may rise. Companies must weigh the benefits against potential challenges.

Collaborative robots, or cobots, also deserve consideration. They are designed to work alongside humans, enhancing productivity. Yet, integrating these devices into existing workflows may disrupt established processes. Understanding team dynamics is crucial, as friction can occur. A robust evaluation of these factors is essential for making informed decisions about robotic solutions.

When assessing budget and cost-benefit analysis for robot implementation, clarity is key. Businesses must evaluate the initial investment versus long-term savings. According to a recent industry report, companies can save up to 30% on operational costs with the right robotic solutions. However, upfront costs can be daunting.

It’s important to conduct a thorough cost analysis. Include expenses such as maintenance, training, and potential downtime. Often, hidden costs appear after implementation. A study found that approximately 20% of robot projects exceed the original budget. This requires careful consideration.

Tips: Define your ROI. What are your goals? A clear objective can guide your investment. Also, involve your team in discussions. They can provide insights into potential challenges. Balancing expectations and reality can lead to better outcomes.

Remember that not every solution is a fit. Some robots may not integrate well into existing workflows. Businesses can run into compatibility issues. Awareness of these factors is crucial. Evaluation should be an ongoing process. Regularly review performance post-implementation to ensure expectations align with reality.

| Robot Type | Initial Investment ($) | Annual Maintenance Cost ($) | Estimated Annual Savings ($) | Payback Period (Years) |

|---|---|---|---|---|

| Industrial Robot | 75,000 | 5,000 | 25,000 | 2.0 |

| Service Robot | 50,000 | 3,000 | 15,000 | 2.0 |

| Collaborative Robot (Cobot) | 30,000 | 2,000 | 10,000 | 2.0 |

| Automated Guided Vehicle (AGV) | 60,000 | 4,000 | 20,000 | 2.5 |

| Drones | 40,000 | 1,500 | 12,000 | 2.5 |

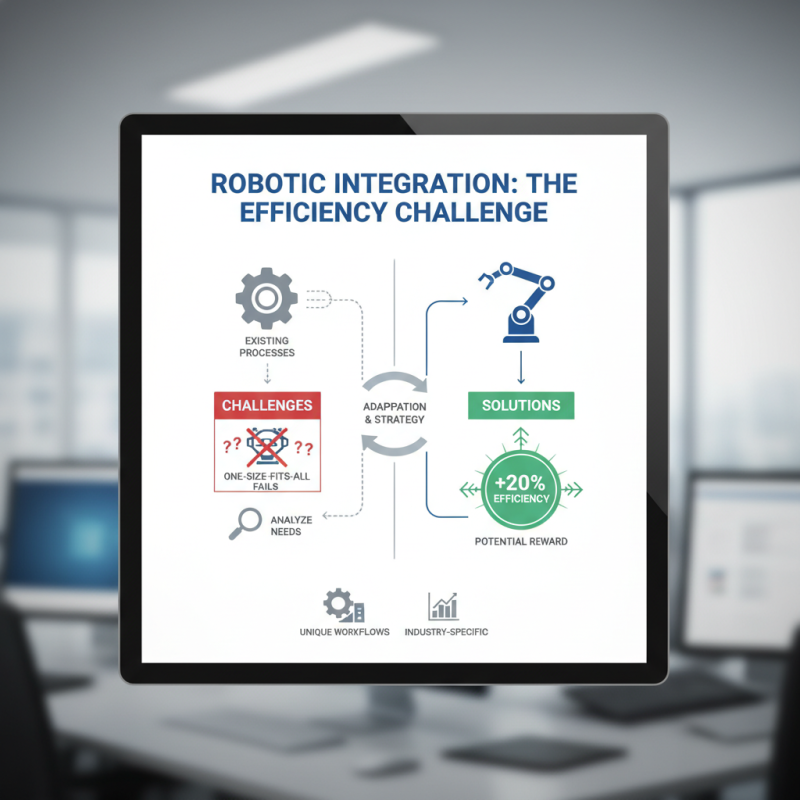

Integrating robot solutions with existing business processes can be challenging yet rewarding. Many businesses see a 20% increase in efficiency after automation. Yet, this is not guaranteed. Each industry has unique workflows. A one-size-fits-all approach often fails. Companies must analyze their specific needs before adopting robotics.

Consider the operational areas that are most repetitive. Tasks like inventory management or data entry can benefit greatly from automation. According to a recent study, 75% of companies that integrated automation into these areas reported significant cost savings. However, the transition requires careful planning. Employees may resist changes, fearing job loss or increased workloads. Training and communication are vital.

Successful integration also depends on the compatibility of new systems with existing technology. If the integration process is not smooth, it can lead to data silos and operational disruptions. A report highlighted that 15% of businesses faced integration challenges that halted productivity temporarily. It’s critical to have a phased approach, allowing teams to adapt gradually while ensuring continuous operations. Balancing innovation with practicality often requires reflection and adjustment.

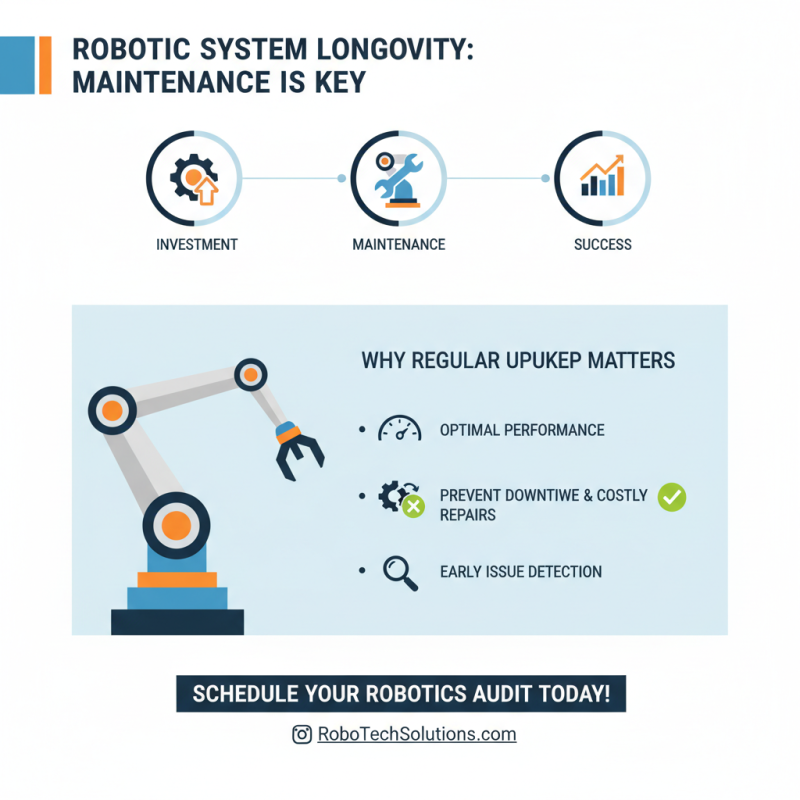

Maintaining and upgrading robotic systems is vital for long-term success. Many businesses invest heavily in robotics. However, they often overlook the need for regular maintenance. Neglect can lead to systems that underperform. Machines may break down, resulting in costly downtimes. It’s crucial to establish a routine upkeep schedule tailored to your specific robots. Regular checks can help pinpoint potential issues before they escalate.

Upgrading systems is equally important. Technology evolves rapidly, and so do business needs. To stay competitive, it’s necessary to assess your robots regularly. Are they meeting current demands? Can they adapt to new tasks? A thoughtful evaluation can help identify gaps. Implementing small updates can significantly enhance performance. Sometimes, even software tweaks can make a difference.

Reflection is key here. Businesses often hesitate to invest in upgrades or maintenance. This can stem from budget constraints but ignoring these needs can be costlier in the long run. Learning from previous maintenance failures can provide critical insights. By being proactive rather than reactive, you can safeguard your robotics investments and streamline operations effectively. Remember, the goal is longevity and efficiency in an ever-changing market.