- sale@instructrobot.com

- Dallas, TX , United States

Selecting the appropriate automation solutions is crucial for enhancing productivity and efficiency in today’s competitive business landscape. Among the vast array of options available, Fanuc industrial robots stand out as a leading choice for many manufacturing industries. Their versatility, precision, and reliability make them an ideal fit for a variety of applications, from assembly lines to intricate machining tasks. However, with an extensive range of models and configurations, the process of choosing the right Fanuc industrial robots can be daunting for business owners and managers alike.

In this guide, we aim to simplify your decision-making process by providing essential tips that will help you evaluate your specific needs and choose the most suitable Fanuc industrial robots for your operations. By understanding your production requirements, potential ROI, and the unique features of different robot models, you can make an informed choice that aligns with your business goals. Whether you are looking to upgrade your current machinery or invest in automation for the first time, these tips will serve as a valuable resource in ensuring that you select the right robotic solution to optimize your manufacturing processes.

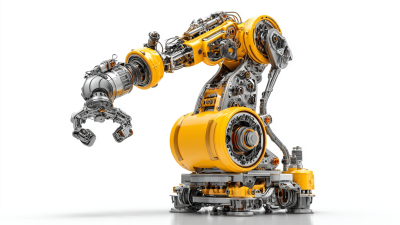

When considering automation through industrial robots, understanding your business needs is crucial to selecting the right equipment. Start by assessing the specific tasks that require automation. Consider factors such as the volume of production, the complexity of tasks, and desired precision. For instance, if your operations involve repetitive tasks that require high accuracy, it’s essential to choose a robot that excels in precision handling. Identifying these parameters will help filter options that truly align with your operational goals.

In addition to task evaluation, it’s important to consider future growth and scalability. Choose robots that not only meet current requirements but can also adapt to evolving business demands. Flexibility in programming and reconfiguration capabilities can provide longevity and adaptability to changing workflows. Lastly, involve key stakeholders in the decision-making process, ensuring that the chosen automation solutions align with your overall business strategy and workforce capabilities. This collaborative approach will enable a smoother integration of technology into your operations, ultimately enhancing productivity and efficiency.

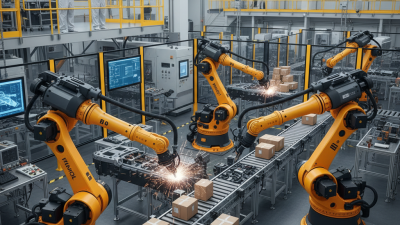

When selecting the right industrial robot for your business, it’s essential to evaluate different models based on their specific applications. Each robot variant is engineered to excel in particular tasks, ranging from assembly and welding to packaging and material handling. Understanding the unique strengths of each model is crucial. For instance, some robots may have enhanced precision for intricate tasks, while others are designed for speed and efficiency in high-throughput environments. Assessing the nature of your production line and the tasks at hand will help in making a more informed choice.

Additionally, the flexibility and adaptability of a robot are key factors to consider. Some models come equipped with advanced programming capabilities, allowing them to switch between multiple tasks with relative ease. This adaptability can be beneficial for businesses that need to adjust their operations frequently. Furthermore, examining the payload capacity and reach of the robots is vital; ensuring that the chosen model can handle the weight of the materials and products being processed will directly impact efficiency and safety. Overall, thorough evaluation aligned with your operational needs will guide you to the most suitable industrial robot solution.

| Robot Model | Payload Capacity (kg) | Reach (mm) | Typical Application | Control System |

|---|---|---|---|---|

| Model A | 5 | 900 | Assembly | R-30iB |

| Model B | 10 | 1200 | Material Handling | R-30iB |

| Model C | 15 | 1500 | Welding | R-30iB |

| Model D | 20 | 1800 | Painting | R-30iB |

| Model E | 30 | 2000 | Heavy Assembly | R-30iB |

| Model F | 8 | 1000 | Pick and Place | R-30iB |

| Model G | 25 | 1600 | Collaboration | R-30iB |

| Model H | 12 | 1100 | Quality Control | R-30iB |

| Model I | 18 | 1400 | Packaging | R-30iB |

| Model J | 28 | 1700 | Food Processing | R-30iB |

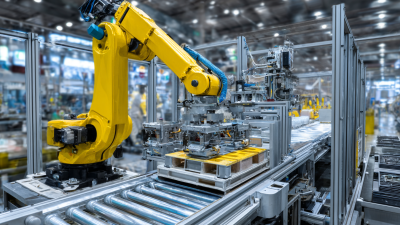

When choosing the right industrial robots, assessing their integration capabilities with existing systems is crucial for operational efficiency. According to a report by MarketsandMarkets, the global industrial robotics market is projected to grow from $43.9 billion in 2020 to $73.9 billion by 2026, driven by the demand for automation across various sectors. Thus, ensuring that the robots you select can seamlessly work with current machinery and software is imperative for maximizing return on investment and minimizing downtime.

One key tip for achieving smooth integration is to evaluate the communication protocols supported by the robots. Robots that can easily connect with your existing systems through common communication standards will facilitate faster implementation and reduce the complexity often associated with integrating new technology. Additionally, conducting a thorough analysis of your existing workflows can reveal areas where robotic automation can enhance efficiency. Research by the International Federation of Robotics indicates that 75% of manufacturers believe that integrating new robots will lead to reduced operational costs and improved productivity.

Moreover, considering the scalability of the robotic solutions you choose is essential. As your business grows, the flexibility of the robotic systems to adapt to new tasks or expanded operations will play a vital role in your ongoing success. Opt for systems that allow for easy upgrades or additions without requiring a complete overhaul of your existing setup. By prioritizing these integration capabilities, businesses can ensure that their investment in robotics yields sustainable benefits over the long term.

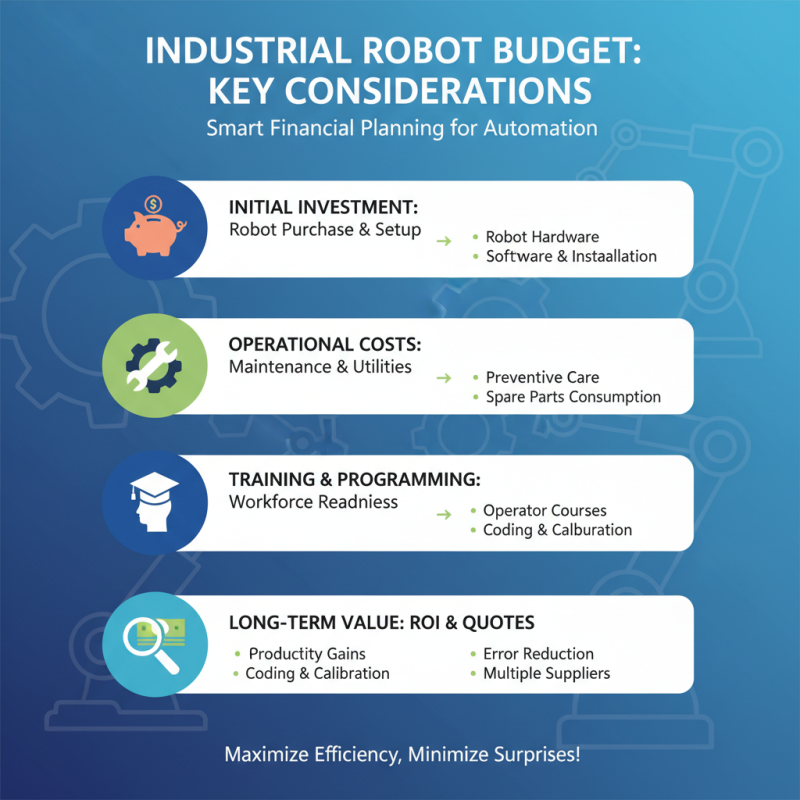

When selecting the right industrial robots for your business, understanding and determining your budget and cost considerations is crucial. The initial investment can be significant, so it's essential to create a detailed budget that not only covers the purchase of the robots but also considers installation, maintenance, and training costs. Obtaining quotes from multiple suppliers can provide a clearer perspective on the market price, allowing for more informed financial planning.

One of the key tips is to evaluate the total cost of ownership (TCO) rather than just the upfront cost. This includes operational costs, expected lifespan, and potential savings from increased efficiency and reduced labor costs. Also, consider the flexible financing options that some suppliers offer, which can ease initial financial burdens.

Additionally, it's important to account for ongoing operational costs, including energy consumption and maintenance. Opting for energy-efficient models can reduce long-term expenses, making your investment more sustainable. Implementing a phased approach can also help manage costs effectively—starting with a smaller unit and expanding as your budget allows can lead to a more manageable financial commitment while you gauge the performance and ROI of the technology.

When selecting industrial robots for your business, it is crucial to focus on the support and maintenance services that are available to ensure your operations run smoothly. Choosing a robotic system goes beyond just evaluating the robot's specifications; the after-sales support can significantly affect your investment's longevity and performance. It's essential to research the service offerings provided by the manufacturer, including responsiveness, accessibility, and the expertise of the support team. This can often make a quantitative difference in production downtime and efficiency.

One of the key tips is to look for comprehensive maintenance plans that suit your operational needs. A solid support framework should include regular preventive maintenance services, on-call repairs, and timely updates. Additionally, ensure that training is included to familiarize your team with troubleshooting and routine maintenance practices. Well-structured training programs help to empower your staff, which can minimize downtime and enhance productivity.

Another important consideration is to evaluate the availability of replacement parts and the predictability of service visits. Knowing that parts can be sourced quickly and that technicians are readily available reduces uncertainty and allows for better operational planning. Establishing a relationship with a provider that prioritizes customer support will pay off in terms of reliability and efficiency in the long run.