- sale@instructrobot.com

- Dallas, TX , United States

Determining the cost of a palletizing robot is crucial for many businesses. Various factors influence the total expense. Understanding these elements can help you make informed decisions.

Palletizing robot cost can vary widely based on specifications. The complexity of the task, the robot’s payload capacity, and the level of automation all play vital roles. Additionally, you must account for installation expenses and maintenance requirements.

Some companies underestimate ongoing costs. Hidden fees can arise, making budgeting a challenge. Reflecting on these aspects is necessary for realistic financial planning. Consider not just the purchase price, but the long-term implications of your investment.

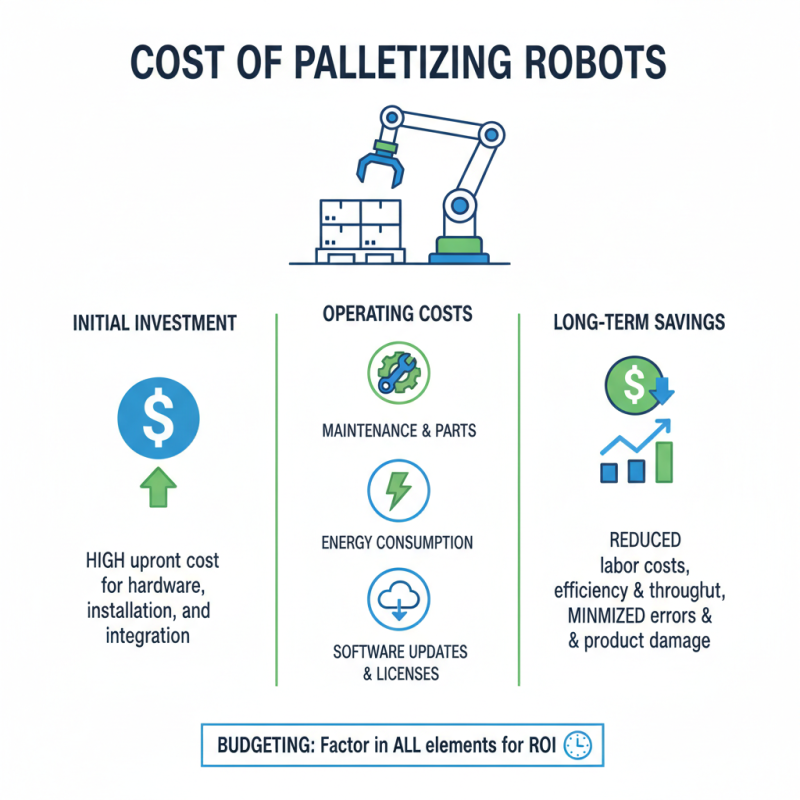

Palletizing robots are essential for streamlining operations in warehouses and factories. These machines handle the stacking of products efficiently. Understanding their costs involves several factors. Initial investment is often high. However, the long-term savings can be substantial. Maintenance, energy consumption, and software updates also add to the cost. It's important to factor in these elements when budgeting.

Training staff to operate and maintain these robots is another expense. Employees need skills to troubleshoot unexpected issues. The complexity of different models can lead to confusion. It's essential for companies to consider potential disruptions during implementation. Installation timelines can vary significantly among projects. This often leads to unanticipated downtime.

Considering the return on investment (ROI) is crucial. While upfront costs might deter some, efficiency gains often offset these concerns. Users may not reach optimal efficiency initially, leading to reflections on the selection process. Analyze specific needs to avoid pitfalls. Accurate cost calculation helps in making informed decisions about integration.

When considering the cost of palletizing robots, several factors come into play. The initial investment varies widely based on the robot's capabilities. According to a recent industry report, basic robotic systems cost between $25,000 and $50,000, while advanced models can exceed $100,000. This significant disparity often stems from the complexity of the technology involved.

Another important consideration is the operational cost. Robots require maintenance, programming, and occasional upgrades. Regular maintenance can add another 10% to 15% of the robot's cost annually. The total cost of ownership must be factored in when assessing budget constraints. Additionally, performance metrics matter. Robots with higher speed and payload capacity often command higher prices. A report indicated that increasing the speed of a palletizer could enhance productivity by up to 30%, partly justifying those costs.

Moreover, the chosen application impacts pricing significantly. Custom solutions can lead to increased costs, sometimes ranging 30% higher than standardized models. The integration process also requires skilled labor, which can further strain budgets. Investing in training for staff ensures that these robots are used efficiently, but it may increase upfront expenses. Reflecting on these factors can lead to informed decision-making in the quest for cost-effective palletizing solutions.

When considering palletizing automation, the return on investment (ROI) is crucial. It helps justify the initial costs. You can start by calculating labor savings. Evaluate how many hours workers currently spend on palletizing tasks. Multiply this by labor costs to find potential savings.

Tips: Don't forget to factor in maintenance costs. These ongoing expenses can add up. Ensure you have a comprehensive view of all costs, not just initial investments.

Next, analyze productivity gains. How much faster and more accurately can a robot perform? Increased throughput leads to higher revenue. You can also consider improvements in workplace safety. Automated systems reduce the risk of injuries, which can save on insurance and compensation.

Tips: Monitor the learning curve for employees. They may need training to work alongside robots. This aspect can impact the overall ROI, so plan accordingly.

Lastly, think about the lifespan of the equipment. Quality robots often last longer, providing more return over time. Consider scaling options as well. Can the system grow with your needs? Addressing these points will lead you toward a clearer understanding of palletizing automation's costs and benefits.

When selecting a palletizing robot, it is essential to analyze different brands and models. Each robot has unique features, which influence performance and cost. Comparing payload capacity, speed, and flexibility helps in making an informed decision. Some robots handle various pallet sizes, while others perform better with specific dimensions. Understanding these capabilities is crucial.

Tips: Consider the long-term operational costs. Maintenance and energy efficiency vary across models. Look for robots that offer easy access for servicing.

Choosing a robot also involves evaluating software compatibility. Some models include intuitive interfaces, making them easier to program. Others might require specialized knowledge. User-friendly models tend to reduce training time.

Tips: Check for customer support and resources offered by manufacturers. Strong support can save time and frustration later. Consider the feedback from existing users, too. Reflections on their experiences can uncover potential issues with certain models.

When evaluating maintenance and operational costs of palletizing systems, consider several factors. First, the type of materials used for the robots can influence longevity. Robots made of high-quality components may incur a higher initial cost but reduce expenses over time. Regular maintenance schedules help prevent unexpected breakdowns.

Tips: Schedule maintenance regularly. This helps avoid larger issues later. Look for patterns in downtime to adjust maintenance frequency.

Training operators properly is essential. Skilled operators can troubleshoot minor issues, minimizing downtime. However, even experienced staff need ongoing education. Innovations in technology could change how machines operate. While this can improve efficiency, it may add to your costs.

Tips: Invest in employee training. Well-trained staff can handle more complex systems. This could save money in the long run.

Monitor energy consumption as well. Robots with better energy efficiency may cost more upfront. They can lead to significant savings in operational costs. Evaluate the total cost of ownership rather than initial purchase price alone. This reflection can reveal surprising insights into long-term expenses.

| Aspect | Estimated Cost ($) | Maintenance Frequency | Operational Cost/Year ($) |

|---|---|---|---|

| Initial Investment | 50,000 | N/A | N/A |

| Annual Maintenance | 5,000 | Quarterly | N/A |

| Energy Consumption | 3,000 | Monthly | 3,000 |

| Labor Costs | 20,000 | N/A | 20,000 |

| Downtime Costs | 10,000 | As Needed | 10,000 |