- sale@instructrobot.com

- Dallas, TX , United States

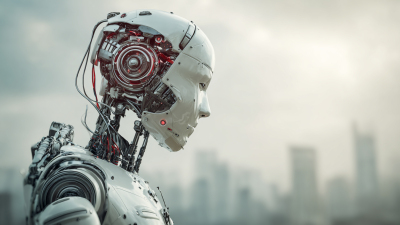

Soft robotics is revolutionizing various industries with its unique applications. According to Dr. Emily Chen, a leading expert in soft robotics, “The future of manufacturing lies in our ability to integrate flexible automation.” This underscores the potential soft robotics holds.

The versatility of soft robots makes them suitable for delicate tasks where traditional robots may fail. For instance, in agriculture, soft robotics can aid in harvesting fruits without damaging them. Yet, challenges remain. Many designs still struggle with reliability in harsh environments. This leads to questions about scalability and efficiency.

Industries are still learning how to effectively implement soft robotics. Many companies hesitate to invest due to uncertainties about long-term benefits. Innovators must strive to improve both functionality and durability in these systems. Only then can the true potential of soft robotics be realized.

Soft robotics is revolutionizing various industries. It focuses on creating machines that mimic the flexibility and adaptability of living organisms. The principles of soft robotics involve using compliant materials like silicone. These materials allow robots to interact safely with their environment and people. According to research by the International Federation of Robotics, the demand for soft robotic applications is projected to grow by 20% annually.

Industries such as healthcare and manufacturing benefit from soft robotics. In healthcare, soft robots assist in rehabilitation. They provide gentle support and adapt to the patient's movements. In manufacturing, soft grippers handle delicate items without causing damage. These applications showcase the versatility and potential of soft robotics.

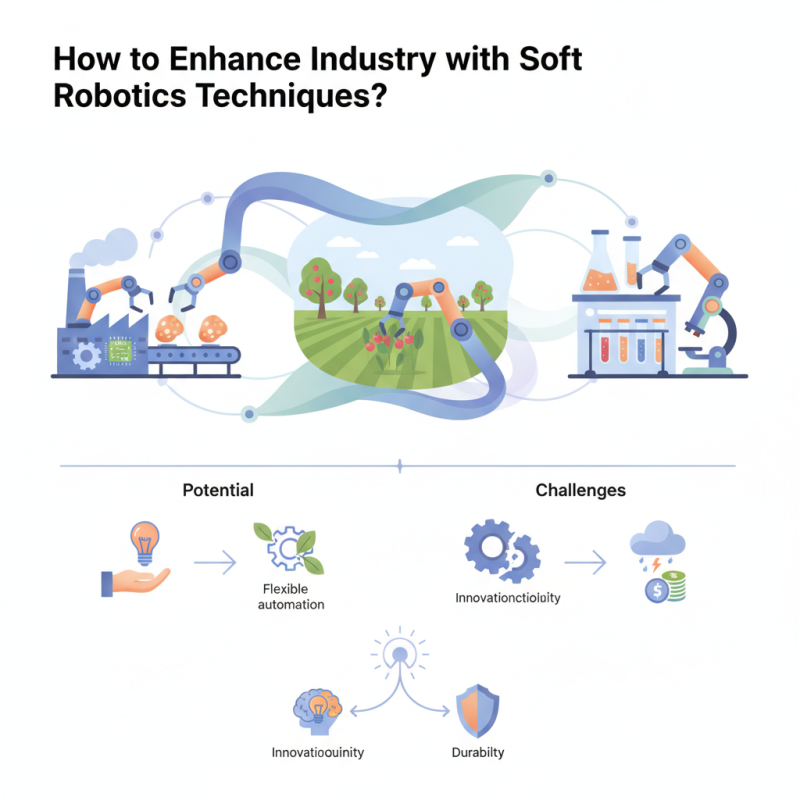

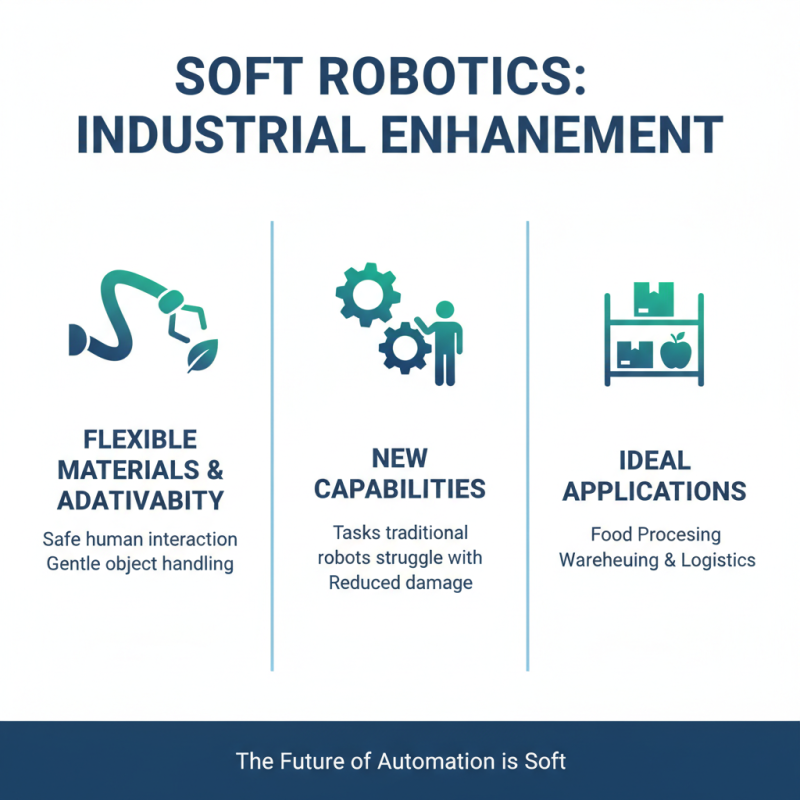

Soft robotics is an emerging field with exciting potential for industrial enhancement. By utilizing flexible and adaptable materials, soft robots can perform tasks that traditional robots struggle with. These robots can safely interact with humans and handle delicate objects without damage. This makes them ideal for industries like food processing and warehousing.

One key technique in soft robotics is the use of soft actuators. These actuators mimic natural movements. They can bend, stretch, and compress, allowing robots to navigate complex environments. Another technique involves employing sensors that provide feedback on their positioning. This can improve accuracy and responsiveness in tasks. Applying these techniques requires careful consideration. Sometimes, soft robots may lack the precision seen in rigid counterparts. This can lead to errors in automated processes.

Moreover, integrating soft robotics into existing systems poses challenges. Not every factory is prepared for such changes. Training workers to interact with these new technologies is essential. Resisting change is common in traditional industries. Innovation often demands effort and adaptation. Embracing these techniques can lead to improvement, but it requires reflection on current practices. Balancing efficiency with adaptability is key for successful implementation.

Integrating soft robotics into existing industries presents numerous advantages. The capabilities of soft robots offer flexibility and safety in fragile environments. For instance, in agriculture, soft robotics can assist in delicate harvesting, boosting efficiency by up to 30%. This technology minimizes crop damage while ensuring a gentle touch.

Moreover, the healthcare sector can greatly benefit. Soft robots have the potential to enhance patient care. In rehabilitation, soft robotic exoskeletons provide gentle support, allowing patients to regain mobility. Reports show that 15% of patients using these devices display significant improvement in recovery times.

However, not all industries are ready for this shift. The initial cost of integrating soft robotics can be daunting. Companies may hesitate to invest due to uncertainties in ROI. Addressing these challenges requires careful planning and a clear understanding of the technology's potential.

Despite the obstacles, the adoption of soft robotics is on the rise. A study indicated that nearly 25% of manufacturers are exploring this technology. As soft robotics continue to evolve, industries willing to adapt may reap substantial benefits. A gradual approach, testing and refining applications, could ensure sustainable growth in this innovative field.

| Industry | Application | Advantages | Challenges |

|---|---|---|---|

| Manufacturing | Assembly Line Automation | Increased flexibility, Reduced risk of damage | Integration with existing systems |

| Healthcare | Surgical Assistance | Enhanced precision, Minimally invasive procedures | Regulatory approval |

| Agriculture | Crop Monitoring and Harvesting | Improved yield, Reduced labor costs | Environmental impact considerations |

| Logistics | Warehouse Automation | Higher efficiency, Better space utilization | Initial investment cost |

| Food Processing | Food Handling | Reduced contamination risk, Enhanced safety | Hygiene compliance |

Soft robotics has begun to revolutionize various industries. One notable case study involves the use of soft robotic grippers in warehouses. These adaptive tools can handle fragile items with care. They mimic the natural movement of human hands. However, they sometimes struggle with heavy objects. This limitation requires ongoing development and testing.

In agriculture, soft robotics has shown promise in harvesting crops. Robotic arms designed with soft materials can gently pick fruits without damaging them. Farmers observed improved yield quality. However, the efficiency of these robots needs improvement. There are instances where they work slower than traditional methods. These challenges highlight areas for further research.

Healthcare applications are intriguing as well. Soft robotic devices are being tested for rehabilitation. Such devices assist patients in regaining mobility. Reports show positive outcomes in patient recovery. Yet, feedback indicates a need for better control and customization. This inconsistency in performance leads to ongoing adjustments in design.

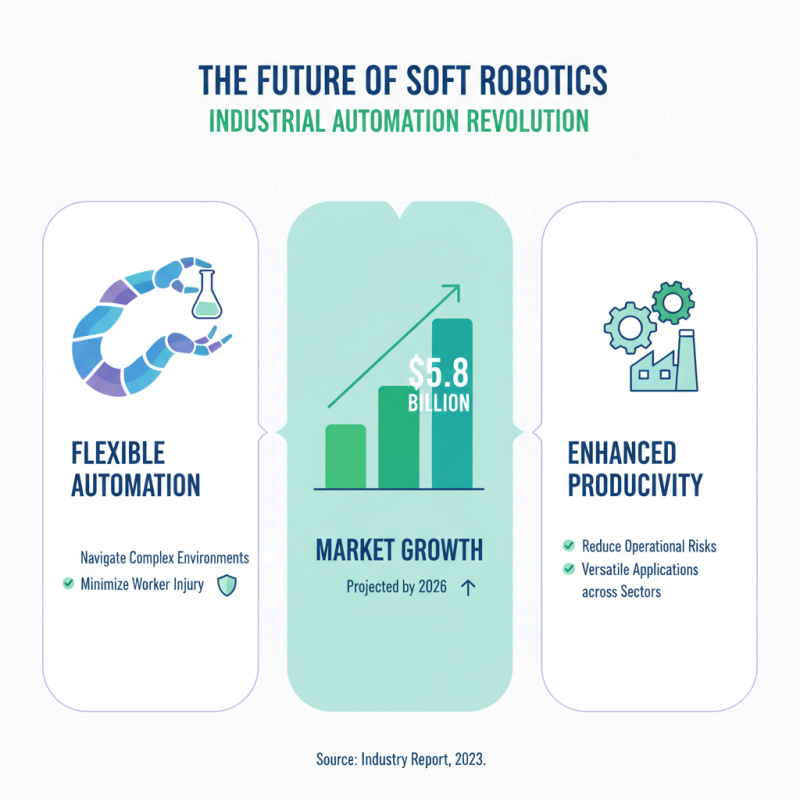

The future of soft robotics in industries looks promising. According to a recent report, the soft robotics market is projected to reach $5.8 billion by 2026. This growth reflects a rising demand for flexible automation in various sectors. Companies are focusing on enhancing productivity while reducing operational risks. Soft robots can navigate complex environments with ease. They minimize the risk of injuries to workers.

Soft robotics applies innovative materials and designs. For instance, silicone-based actuators can mimic human-like movements. These features allow robots to handle delicate objects without causing damage. Industries such as food processing and healthcare are exploring these technologies. However, challenges remain. The integration of soft robotics into existing systems can be complex. Some manufacturers may hesitate due to high initial investment costs.

Moreover, ensuring safety and reliability is crucial. Soft robots must be tested thoroughly in real-world scenarios. The interaction between soft robotics and traditional automation is still developing. Balancing the flexibility of soft robotics with the precision of rigid systems presents ongoing challenges. Adapting to this evolving landscape requires ongoing research and collaboration among experts.