- sale@instructrobot.com

- Dallas, TX , United States

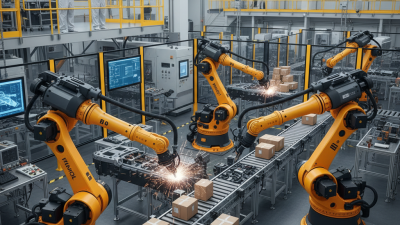

In today's rapidly evolving manufacturing landscape, the integration of assembly robots has become a pivotal factor in enhancing productivity and efficiency. As businesses strive to remain competitive, making informed decisions about the right assembly robots is crucial. Expert in automation technology, Dr. Jane Thompson, asserts, "The choice of assembly robots can define the operational success of a business, influencing not only production rates but also the overall quality of the final product."

Selecting the appropriate assembly robots involves careful consideration of various factors, including the specific tasks they will perform, the environment in which they will operate, and the scalability of the technology. Dr. Thompson emphasizes the importance of aligning robotic capabilities with business objectives, stating that understanding your needs is the first step towards a successful automation strategy.

As companies increasingly turn to automation to meet rising demands and optimize their operations, the insights gathered from industry experts can serve as a valuable guide. Understanding the nuances of assembly robots can empower businesses to make strategic decisions that not only improve efficiency but also foster innovation and growth in their sector.

When considering the integration of assembly robots into your business, it is paramount to first understand your specific operational needs. A thorough assessment of your production requirements, including the types of products being assembled, the volume of output, and the desired level of automation, will guide your decision-making process. According to a report by the International Federation of Robotics (IFR), the global industrial robot market is projected to reach $23.5 billion by 2026, highlighting the increasing reliance on automation across various sectors. This growth underscores the importance of aligning robotic capabilities with the precise tasks your operation necessitates.

Additionally, factors such as workspace configuration, training for personnel, and maintenance routines must be taken into account. A study from McKinsey & Company indicates that automation can increase productivity by up to 30% in assembly lines when robots are effectively integrated into the workflow. Businesses must also evaluate whether they need flexible robots capable of handling diverse tasks or specialized machines designed for high-volume production. Understanding these nuances ensures that your investment in assembly robotics not only meets current demands but also supports future scalability and efficiency.

| Tip Number | Tip Title | Description | Importance Level |

|---|---|---|---|

| 1 | Assess Production Needs | Understand the specific assembly tasks your robots will perform. | High |

| 2 | Evaluate Payload Capacity | Choose robots with the right capacity based on your materials. | Medium |

| 3 | Consider Reach and Workspace | Ensure robots can cover the entire workspace without limitations. | High |

| 4 | Select the Right End Effector | Pick end effectors that suit the assembly tasks. | High |

| 5 | Analyze Integration Capabilities | Check compatibility with existing systems and machinery. | Medium |

| 6 | Examine Programming Ease | Choose robots that allow for simple programming and reprogramming. | Medium |

| 7 | Assess Safety Features | Ensure the robots have necessary safety protocols and features. | High |

| 8 | Review Maintenance Requirements | Consider the frequency and type of maintenance required. | Medium |

| 9 | Research Vendor Support | Choose a vendor that offers strong post-purchase support. | High |

| 10 | Budget Considerations | Factor in the total cost of ownership vs just the purchase price. | High |

When evaluating the types of assembly robots available in the market, it's essential to understand the various categories that cater to different business needs. Industrial robots, such as articulated robots, SCARA robots, and delta robots, each offer unique advantages depending on the complexity and precision required for specific tasks. For instance, articulated robots are typically favored in automotive assembly due to their flexibility and range of motion, while SCARA robots are ideal for high-speed assembly operations in electronics manufacturing. According to a recent report by the International Federation of Robotics (IFR), the demand for articulated robots has surged by 12% annually, reflecting their versatility across various sectors.

Moreover, collaborative robots, or cobots, have emerged as a significant player in the assembly line, designed to work alongside human operators safely. Their user-friendly interfaces and adaptive capabilities make them suitable for small to medium enterprises. The IFR estimates that by 2025, cobot sales will constitute over 29% of all industrial robot sales, driven by their ability to enhance productivity without the need for extensive safety installations. Therefore, businesses must assess their specific needs and the operational environment to select the right type of assembly robot, ensuring an effective integration that optimizes workflow while maintaining safety standards.

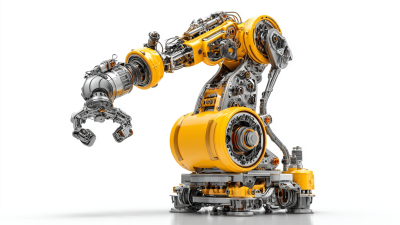

When selecting assembly robots for your business, understanding the right specifications and features is crucial for enhancing efficiency and productivity. One of the critical factors to consider is the payload capacity of the robot, which should align with the weight and dimensions of the components it will handle. According to a recent report by MarketsandMarkets, the payload capacities of industrial robots are expected to evolve significantly, with a projected CAGR of over 12% in the coming years. This data indicates that businesses must assess their current and future production requirements to choose a robot that can accommodate varying loads seamlessly.

In addition, the range of motion and speed of the robot are key specifications that impact operational efficiency. The International Federation of Robotics (IFR) reports that faster robots can increase assembly line speeds by up to 25%, reducing cycle times and minimizing bottlenecks. Additionally, businesses should consider features like programmability and ease of integration with existing systems. A flexible robot that can be easily reprogrammed for different tasks can significantly reduce downtime and operational costs. Evaluating these specifications in the context of your unique operational needs can lead to more informed decisions and successful automation initiatives.

When considering the integration of assembly robots into your business, one crucial factor to evaluate is the total cost of ownership (TCO). TCO encompasses not only the initial purchase price, but also ongoing expenses associated with operation, maintenance, and potential downtime. It's essential to analyze these components to create a clearer financial picture before committing to a specific robot system. Companies often overlook costs such as energy consumption, software updates, and the need for specialized training for staff, which can significantly influence the overall investment.

Another key aspect of TCO is the longevity and adaptability of the assembly robots. Investing in a robot that can be easily updated or reprogrammed for different tasks reduces the risk of obsolescence and maximizes your return on investment. Additionally, assessing the reliability and availability of spare parts can help mitigate unexpected operational disruptions. By thoroughly evaluating these factors, you can make a more informed decision that aligns with your business’s long-term strategic goals, ensuring that the robotic system you choose not only meets current demands but can also grow with your evolving production needs.

When considering the incorporation of assembly robots into your business, an effective first step is thorough research on leading manufacturers in the field. The global robotics market is projected to reach a valuation of $210 billion by 2025, indicating a significant growth trajectory that highlights the increasing reliance on automation in manufacturing processes. A strong understanding of various assembly robot manufacturers, their offerings, and technological advancements is paramount to making a well-informed decision.

To streamline your comparison, focus on key parameters such as customization options, ease of integration, and support services offered by different manufacturers. According to a recent report by the International Federation of Robotics, the automotive industry is the largest user of industrial robots, accounting for 27% of all installations, while electronics and consumer goods sectors are also rapidly adopting these technologies. Examine case studies where manufacturers have successfully implemented assembly robots, as this can provide valuable insights into the potential ROI and efficiency gains relevant to your specific industry needs. Evaluating the performance metrics and customer satisfaction ratings of leading manufacturers can further aid in selecting the right assembly robots that align with your business goals.

This bar chart compares the key features of different assembly robots available in the market. The features evaluated include Payload Capacity, Speed, Precision, and Cost. These metrics are crucial for businesses to consider when selecting the right assembly robots to optimize their manufacturing processes.