- sale@instructrobot.com

- Dallas, TX , United States

Efficient material handling is a cornerstone of successful warehouse operations, playing a crucial role in optimizing workflows and minimizing costs. As noted by John Doe, a recognized expert in the material handling industry, "Effective material handling not only improves productivity but also enhances safety and reduces operational costs." His insights underscore the significance of implementing thoughtful strategies to manage materials throughout the warehouse environment.

In today’s fast-paced business landscape, the efficiency of warehouse operations is paramount. From receiving goods to storage and ultimately shipping, each aspect of material handling can impact overall productivity. By employing systematic approaches and incorporating the latest technologies, warehouses can streamline their processes, ensuring that materials are moved swiftly and safely. This article will explore ten essential tips that can drastically improve the efficiency of material handling in your warehouse operations, providing practical advice that can lead to better performance and greater profitability.

Efficient material handling is fundamental to the success of warehouse operations. It not only streamlines processes but also significantly impacts productivity, costs, and overall service quality. By optimizing the way materials are received, stored, and distributed, warehouses can minimize waste, reduce handling times, and improve order accuracy. Understanding the nuances of efficient material handling allows warehouse managers to implement strategies that enhance workflow and ensure that resources are used effectively.

The importance of efficient material handling extends beyond just operational efficiency; it also contributes to employee safety and satisfaction. A well-organized warehouse reduces the risk of accidents and injuries by ensuring that pathways are clear and storage is accessible. Moreover, when employees can move materials easily and quickly, it fosters a more productive work environment. Training staff on best practices and investing in appropriate equipment can further enhance these benefits, making the workforce more agile in responding to changing demands while maintaining high service levels.

Effective material handling is pivotal for the success of warehouse operations. One key principle is optimizing layout design to minimize travel distance for both workers and equipment. By strategically arranging storage areas, packing stations, and equipment, warehouses can reduce time wasted moving between tasks. Implementing clear signage and well-defined pathways ensures smooth transitions and enhances safety, which is crucial in maintaining an efficient workflow.

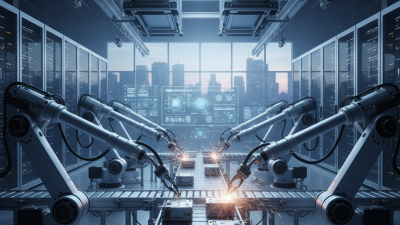

Another essential aspect is the adoption of technology to streamline processes. Integrating automated systems such as conveyor belts, automated guided vehicles (AGVs), or warehouse management software can significantly increase handling efficiency. These technologies not only reduce the potential for human error but also allow for real-time inventory tracking, ensuring that restocking occurs promptly and reducing the risk of stockouts. Training staff to effectively use these technologies also plays a vital role in fostering a culture of efficiency, ensuring that employees are well-equipped to handle materials swiftly and safely.

| Tip Number | Tip Description | Benefits | Implementation |

|---|---|---|---|

| 1 | Optimize Layout | Improved space utilization | Conduct a layout analysis |

| 2 | Use Automated Systems | Increased efficiency and accuracy | Invest in robotics or conveyor systems |

| 3 | Implement Training Programs | Reduced errors and injuries | Schedule regular training sessions |

| 4 | Use Proper Material Handling Equipment | Improved safety and efficiency | Conduct equipment audit and provide necessary tools |

| 5 | Standardize Processes | Consistency in operations | Document and communicate standardized procedures |

| 6 | Implement Inventory Management Software | Better tracking and reduced stockouts | Choose and train on an appropriate software |

| 7 | Conduct Regular Audits | Identify inefficiencies | Schedule audits quarterly |

| 8 | Optimize Loading and Unloading | Faster turnaround times | Use designated loading zones |

| 9 | Improve Communication | Better coordination among teams | Use communication tools effectively |

| 10 | Track Performance Metrics | Identify areas for improvement | Regularly review key performance indicators |

In today's fast-paced warehouse environment, implementing technology solutions is vital for optimizing material handling processes. Automation technologies such as conveyor systems and automated guided vehicles (AGVs) can significantly reduce manual labor, minimize human error, and enhance overall efficiency. By integrating these systems, warehouses can streamline the transport of goods from one area to another, ensuring faster processing times and increased productivity. Robotics and AI-driven solutions are revolutionizing how inventory is managed, allowing for real-time tracking and improved stock accuracy.

Moreover, software solutions play a crucial role in material handling efficiency. Warehouse Management Systems (WMS) facilitate better inventory control, helping managers make informed decisions based on accurate data. These systems can automate order fulfillment processes and optimize picking routes, directly impacting throughput and reducing delays. As warehouses embrace technologies like RFID tagging and mobile scanning devices, they gain deeper insights into inventory levels and reduce the chances of stockouts or overstock situations. By adopting these innovative technologies, warehouses not only enhance their material transport but also create a more responsive and agile operation capable of meeting evolving market demands.

Effective workforce training is paramount for ensuring efficiency in material handling within warehouse operations. A well-trained workforce not only enhances productivity but also minimizes the risk of workplace accidents. Implementing a structured training program that covers essential skills such as proper lifting techniques, equipment operation, and hazard identification is crucial. Regular training sessions and refreshers should be conducted to keep employees updated on best practices and safety protocols, ensuring that every team member understands their responsibilities and the importance of adhering to safety measures.

In addition to training, the establishment of robust safety measures is vital to maintaining an efficient material handling process. This includes the implementation of clear standard operating procedures (SOPs) for various tasks, regular safety audits, and accessible emergency protocols. Ensuring that all employees wear appropriate personal protective equipment (PPE) can significantly reduce the risk of injury. Creating a culture of safety where employees feel empowered to report potential hazards can further enhance the overall efficiency of material handling operations. By prioritizing training and safety, warehouses can achieve not only higher productivity but also a healthier work environment for all employees.

Periodic assessment and improvement of material handling practices are crucial for maintaining efficiency in warehouse operations. Regular evaluations allow managers to identify bottlenecks and gaps in current systems. Engaging staff in these assessments can provide valuable insights from those on the front lines, ensuring that any changes align with daily workflows and challenges.

One essential tip is to implement a structured process for conducting these assessments at scheduled intervals. This could involve reviewing key performance indicators (KPIs) related to material handling, such as picking accuracy, order fulfillment time, and employee productivity. By analyzing this data, management can make informed decisions about necessary changes or upgrades.

Another tip is to encourage continuous feedback from workers who handle materials every day, as their firsthand experience can highlight inefficiencies and suggest practical solutions.

Additionally, investing in training programs can significantly enhance the effectiveness of material handling systems. Regular training ensures employees are up-to-date on best practices and new technologies that streamline operations. By incorporating these training sessions into periodic assessments, organizations can foster an adaptive culture that embraces improvement. Ultimately, a cycle of evaluation and enhancement not only boosts operational efficiency but also contributes to a safer and more productive work environment.