- sale@instructrobot.com

- Dallas, TX , United States

In today's fast-paced supply chain environment, efficiency is key. According to Dr. Emily Zhang, a leading expert in robotic automation, "Embracing robot picking systems can transform warehouse operations." Robot picking systems allow companies to streamline their inventory handling processes. Implementing these systems can lead to significant time and cost reductions.

However, not all businesses achieve the desired efficiency with robot picking. Challenges exist, such as integration with existing systems and worker training. Some companies find it difficult to adapt to rapid technological changes. Additionally, the initial investment may deter some managers from pursuing this technology.

Despite these challenges, robot picking systems present immense potential. The combination of precision and speed can enhance productivity. Companies must reflect on their specific needs and resources. Embracing this transformative technology requires careful planning and the right mindset. Only then can the benefits of robot picking be fully realized.

Robot picking systems are transforming warehouse operations, significantly boosting productivity. Reports show that companies using robotic picking can see a 20% increase in order fulfillment rates. These systems efficiently manage inventory, reduce errors, and lower labor costs.

One key factor in enhancing productivity is optimizing the layout for robotic systems. A well-organized space allows robots to navigate quickly. It’s essential to analyze the flow of items and strategically place frequently picked products within easy reach. This reduces downtime and increases picking speed, truly impacting efficiency.

Tip: Regularly review your system’s performance metrics. Are robots operating at full capacity? Small adjustments in layout or workflow can lead to noticeable gains. Additionally, ensure staff are adequately trained to work alongside robots. Miscommunication can disrupt workflows and hamper efficiency. Emphasis on teamwork is critical, even with machines involved.

Robot picking systems are transforming warehouse efficiency. Key technologies driving these improvements include advanced sensors, machine learning, and automation software. According to a recent industry report, companies using robot picking have increased their order fulfillment rates by up to 30% in just one year.

Sensors are essential. They allow robots to navigate complex environments. LIDAR and stereo cameras help robots identify and grasp items accurately. However, outdated sensor technologies can lead to errors. Efficiency drops when robots misidentify products or navigate poorly.

Machine learning plays a crucial role too. It enables robots to learn from past experiences, improving their picking accuracy over time. A study highlighted that machine learning integration can boost productivity by 15%. Yet, continuous training is necessary. Systems require regular updates to maintain performance. Automation software coordinates multiple robots, ensuring streamlined operations. However, without proper oversight, issues can arise, such as communication errors among devices. The balance of technology and human oversight is vital for success.

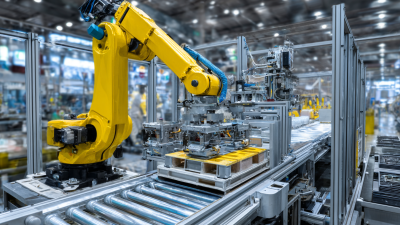

Industries worldwide are deploying robot picking systems to enhance efficiency. These systems have demonstrated significant improvements in operational performance. For instance, a major study indicated that warehouses using robotic systems can boost order processing speeds by up to 300%. In addition, accuracy rates for picking can exceed 99%, drastically reducing errors. Companies report notable reductions in labor costs as automation takes over repetitive tasks.

Case studies reveal that manufacturers are particularly benefiting. One facility reported a 50% reduction in labor hours after adopting robotic picking. Another distribution center saw a 30% increase in throughput. These results are compelling and highlight the importance of embracing technology. However, there are challenges too. Some organizations face integration issues with existing systems. Others struggle with maintenance costs.

**Tip:** Start with a pilot project. Evaluate performance metrics before scaling up.

It’s vital to consider the human element. Employee training is crucial for a smooth transition to automated systems. Listening to employee feedback can identify potential challenges early. **Tip:** Keep communication lines open during implementation. Capture insights that may improve processes. Balancing automation with human skills leads to sustainable growth.

The rapid advancement of robot picking systems has transformed order fulfillment. These technologies can significantly increase speed and accuracy. In warehouses, robots navigate through aisles to pick items with minimal human intervention. This automation reduces human error, making order fulfillment faster.

Statistics show that using robots can improve order processing time by up to 30%. However, the impact might vary depending on the layout of the facility. Some warehouses may not fully utilize robotic efficiency due to their design. It is crucial to assess how the system integrates with existing operations. Poor integration can lead to bottlenecks rather than solving them.

Workers may face challenges adjusting to this shift. The introduction of robots might raise concerns about job security. Training employees to collaborate with robots is essential. Balancing automation with a skilled workforce is key. Despite the advantages, organizations must evaluate both the technology and their staff's readiness for change. This reflection can guide more effective implementations.

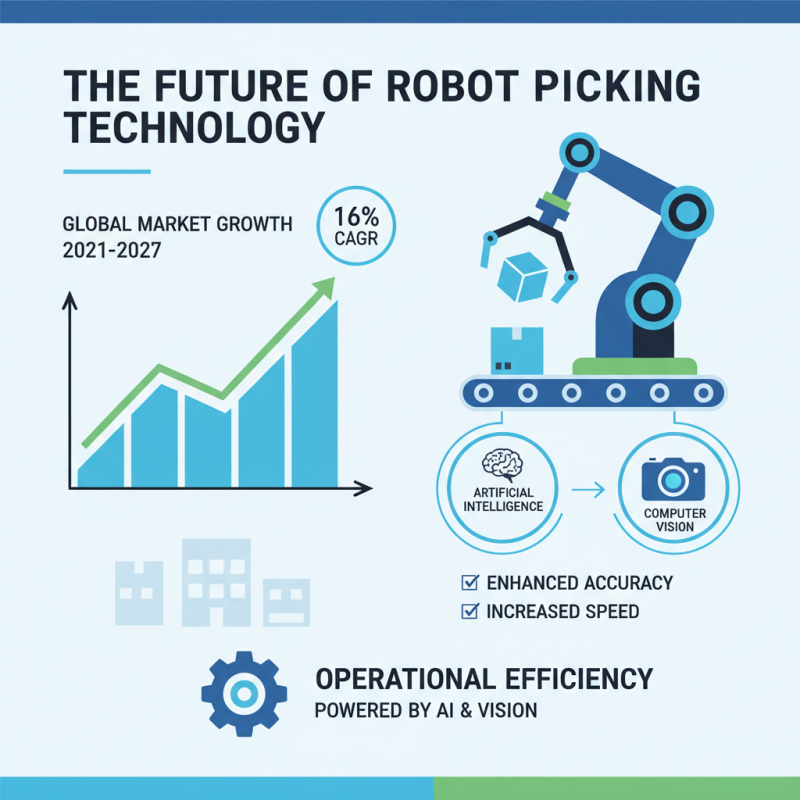

The future of robot picking technology is bright, with significant trends shaping operational efficiency. The global market for robot picking systems is expected to grow at a CAGR of 16% from 2021 to 2027. This growth is driven by advancements in artificial intelligence and computer vision. Companies are leveraging these technologies to enhance accuracy and speed in warehouse operations.

Tips: Invest in training your staff on new technology. This minimizes disruptions and maximizes the benefits of automation. Also, consider integrating different types of robots. Each robot has unique strengths, and using a mixed fleet can optimize workflow.

New sensor technology is improving robot navigation and item handling. However, challenges like high initial costs can deter some businesses. The cost of establishing a fully automated picking system can range from $500,000 to $2 million. Companies must weigh these costs against potential savings and efficiency gains.

Tips: Start small. Implement pilot projects to test the waters before full-scale adoption. This allows you to measure the ROI effectively. Regularly assess your system's performance. Continuous improvement will be essential to stay competitive as technology advances.