- sale@instructrobot.com

- Dallas, TX , United States

As we approach 2025, the transformative potential of soft robotics in enhancing automation is gaining unprecedented attention across various industries. Pioneering expert in the field, Dr. Elizabeth M. Smith, emphasizes the significance of soft robotics by stating, "The future of automation lies in the adaptability and safety that soft robotics can bring to human-robot interactions." This insight highlights the unique advantages of soft robotics, which utilizes compliant materials to create robotic systems that can perform delicate tasks without the risks associated with traditional rigid robots.

Incorporating soft robotics into automation strategies not only enhances efficiency but also ensures that these systems can work alongside humans in a safe and intuitive manner. As industries look to optimize operations for the future, soft robotics presents innovative solutions that enable more flexible and responsive workflows. The ability of soft robots to mimic natural motion opens new avenues for automation that are both advanced and aligned with evolving workplace dynamics.

As we delve deeper into the applications and developments of soft robotics, it becomes clear that this technology will play a crucial role in shaping the landscape of automation in the coming years. By harnessing the capabilities of soft robotics, businesses can not only increase their productivity but also foster a more collaborative and harmonious environment between humans and machines.

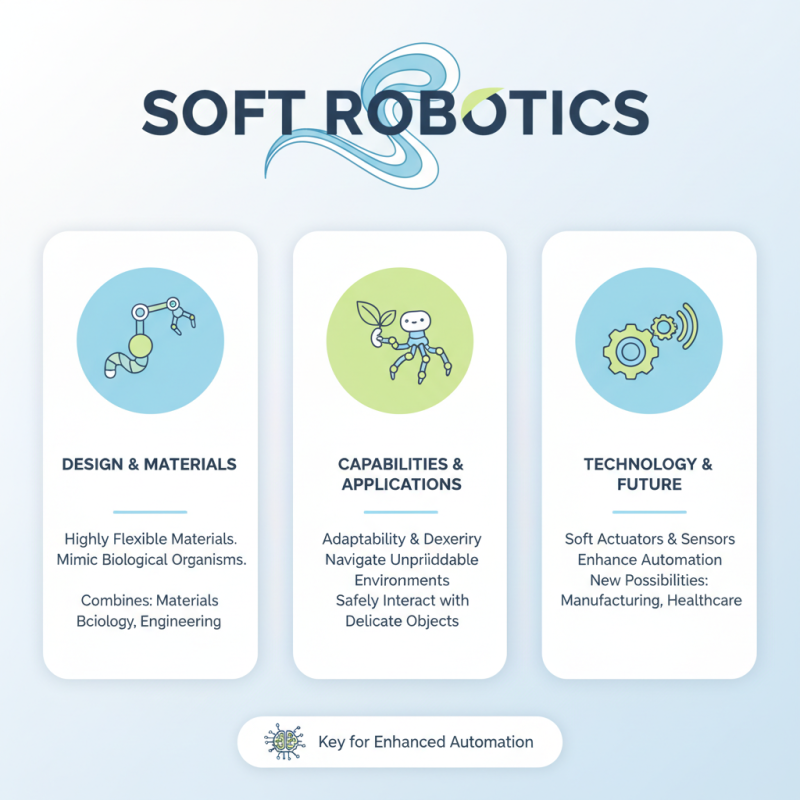

Soft robotics refers to the design and application of robots made from highly flexible materials, allowing them to mimic the adaptability and dexterity of biological organisms. This field combines principles of materials science, biology, and engineering to create robotic systems capable of navigating unpredictable environments. By employing soft actuators and sensors, these robots can safely interact with delicate objects and perform tasks that traditional rigid robots often struggle with. Understanding the principles behind soft robotics is essential for enhancing automation, as it opens up new possibilities for tasks ranging from manufacturing to healthcare.

**Tip:** When exploring soft robotics for automation, prioritize materials that are lightweight yet durable, such as silicone or hydrogels, to ensure both efficiency and safety in operations.

Furthermore, the adaptability of soft robots allows for seamless integration into various workflows. They can be programmed to switch between tasks with minimal downtime, enhancing overall productivity. This capability is particularly beneficial in industries like agriculture, where soft robots can handle fragile crops without damaging them.

**Tip:** Invest in machine learning algorithms that enable soft robots to learn from their environment, allowing them to improve their performance over time and respond dynamically to new challenges.

Soft robotics is revolutionizing industrial automation by providing flexible and adaptive solutions that traditional rigid robotics struggle to achieve. Current applications span across various sectors, including manufacturing, logistics, and agriculture. For instance, soft robotic grippers are being used in assembly lines to delicately handle fragile materials without causing damage, enhancing productivity and reducing waste. This adaptability makes them ideal for tasks that require precision and sensitivity, attributes that are increasingly valuable in modern manufacturing.

**Tips:** When considering the integration of soft robotics into your automation processes, assess the specific tasks that require flexibility. Start with pilot projects to understand the benefits and limitations of soft robotic systems. Training your workforce on these innovative tools is crucial; ensuring that employees are familiar with the technology will facilitate smoother implementation.

In logistics, soft robots can efficiently navigate complex environments, optimizing the movement of goods through warehouses. Their ability to conform to various surfaces allows them to pick and process items in unpredictable layouts, significantly boosting operational efficiency. As industries move toward more automated solutions, the role of soft robotics in enhancing capabilities will only grow, paving the way for more responsive and versatile automation systems.

**Tips:** Evaluate the workspace layout to identify potential areas for soft robotics. Collaborate with soft robotics developers to customize solutions tailored to your specific needs, maximizing the impact of these technologies on operational performance.

The evolution of soft robotics is set to redefine automation across various industries by 2025. Key technologies driving this innovation include advanced materials, AI integration, and sensor technologies. Soft robotics utilize materials that mimic biological systems, allowing for safe interactions with delicate items in manufacturing or healthcare. The flexibility and adaptability of these materials make them ideal for tasks that require precision and gentleness.

Tips: Emphasizing the importance of choosing the right soft materials is crucial. Look for bio-compatible options for applications in healthcare to enhance safety and efficiency. Additionally, consider the integration of AI algorithms to optimize the performance of soft robotic systems. This can significantly improve their ability to learn from and adapt to varying tasks and environments.

As we move forward, the incorporation of tactile sensors will further enhance the capabilities of soft robots. These sensors provide critical feedback in real-time, allowing for adjustments while performing tasks. Companies should invest in research and development of soft robotic systems that can incorporate such sensors to achieve higher levels of automation and operational efficiency.

The implementation of soft robotics solutions poses several challenges that may impact the pace of their integration into various industries by 2025. One key consideration is the complexity of developing soft robotic systems that can meet safety standards while maintaining productivity. According to a report by McKinsey, nearly 30% of manufacturing tasks could be automated using advanced robotics; however, the adaptability of soft robots to handle diverse materials and work alongside humans safely is still under scrutiny.

Moreover, the cost of deploying soft robotics technologies can be a barrier for many organizations. The International Federation of Robotics estimates that the global robotic market will exceed $70 billion by 2025, which highlights the significant investment required for companies looking to enhance automation through these solutions. This financial commitment, coupled with the need for specialized training for employees to work alongside soft robotic systems, complicates the transition for many businesses. Ensuring robust integration of soft robotics while effectively addressing these challenges will be crucial for success in the industry.

As we approach 2025, the field of soft robotics is set to revolutionize automation across various industries. The innovative materials and designs of soft robots allow them to perform tasks that traditional rigid robots struggle with, making them ideal for delicate operations in sectors like manufacturing, healthcare, and agriculture. Future trends will likely see the integration of advanced sensors and AI, enabling these robots to adapt to their environments dynamically and handle complex, nuanced tasks with incredible precision.

Tips for implementing soft robotics in your automation strategy include starting with pilot programs to gauge effectiveness in your specific context, investing in training for your team to understand and leverage these new technologies, and being open to collaboration with tech innovators. Another essential aspect is selecting the right materials that enhance flexibility and sensory capability, ensuring the robots can interact safely and efficiently with their surroundings.

As soft robotics technology advances, innovations such as soft grippers with enhanced dexterity and bio-inspired designs will become more prevalent. These developments will further blur the lines between human and machine work, fostering environments where automation complements human effort rather than replacing it. Embracing these trends will be key for businesses aiming for operational excellence and competitive advantage in the coming years.