- sale@instructrobot.com

- Dallas, TX , United States

In the realm of manufacturing, optimizing industrial robotic systems is crucial. These systems are designed to improve efficiency and reduce costs. However, many industries still struggle with maximizing their potential.

Each robotic system has unique challenges and limitations. For instance, outdated programming might hinder productivity. Often, companies overlook the importance of regular system updates and maintenance. This oversight can lead to inefficiencies and increased downtime.

To truly harness the power of industrial robotic systems, a focus on continuous improvement is essential. Adapting to new technologies can enhance performance. Furthermore, employee training plays a significant role in maximizing system efficiency. As organizations navigate these challenges, a proactive approach will pave the way for innovation and success.

Key Performance Indicators (KPIs) play a crucial role in optimizing industrial robotic systems. They provide measurable values that demonstrate how effectively a company is achieving key business objectives. For robotic systems, common KPIs include uptime, cycle time, and overall equipment effectiveness (OEE). A recent industry report found that improving OEE by just 10% can result in significant cost savings—up to $250,000 annually for manufacturers.

Monitoring these KPIs regularly is essential. Identifying trends can uncover hidden inefficiencies. For example, a cycle time increase might indicate a need for maintenance or adjustments. Many companies overlook such signs, leading to unplanned downtimes. It’s vital to integrate real-time data analytics tools. They allow for more proactive responses to system performance.

However, many organizations struggle with data interpretations. Relying solely on numeric values without context can lead to poor decision-making. In some cases, skewed data can reflect a false sense of security about a robot's efficiency. Thus, successful KPI management requires skilled analysis and a willingness to adapt strategies. Regular training for staff involved can help bridge this knowledge gap in understanding and acting on KPIs.

| KPI | Description | Measurement Method | Target Value | Current Value |

|---|---|---|---|---|

| Cycle Time | Time taken to complete one full cycle of the robotic operation | Timing analysis of production tasks | < 60 seconds | 55 seconds |

| Uptime | Percentage of time the robotic system is operational | Operational logs and scheduling | > 95% | 92% |

| Throughput | Number of units produced in a given time frame | Production records | > 500 units/hour | 480 units/hour |

| Quality Rate | Percentage of products meeting quality standards | Quality inspections and audits | > 98% | 97% |

| Energy Consumption | Amount of energy consumed by the system | Monitoring energy usage | < 50 kWh | 55 kWh |

Predictive maintenance plays a crucial role in enhancing robotics efficiency. By using data analytics, organizations can forecast when a robot might fail. This allows for timely interventions. Implementing predictive maintenance can prevent unplanned downtime, which is costly. Additionally, not every robotic system is equipped with advanced sensors. This gap can lead to missed opportunities for optimization.

Tips: Regularly update your diagnostic tools. This ensures you are capturing all relevant data. Invest in training for staff to interpret analytics better. Knowledge is key.

Regular assessments are vital. Some companies may overlook minor warnings from machines. These signals often indicate deeper issues. Addressing them early can save both time and money. However, it’s common to be reactive rather than proactive. This pattern can hinder overall efficiency.

Tips: Create a checklist for routine machine evaluations. Encourage operators to report anomalies. Foster a culture where maintenance is seen as an essential part of operations.

In today's competitive landscape, optimizing industrial robotic systems is key to achieving maximum efficiency. Advanced programming techniques play a vital role in this optimization. Utilizing algorithms that adapt to varying production demands can greatly enhance productivity. For example, dynamic scheduling can help robots adjust to real-time changes in tasks. This flexibility reduces downtime and maximizes output.

Incorporating artificial intelligence adds another layer of sophistication. AI can analyze data from previous operations, identifying patterns and areas for improvement. However, it is not infallible. Sometimes, AI recommendations may overlook specific nuances of a task. Continuous human oversight is necessary to catch these gaps. Regularly updating the AI model is essential, too. As systems evolve, so must the programming that drives them.

Finding the right balance between automation and human intuition is crucial. While technology can streamline processes, it cannot replace critical thinking. Machines can handle repetitive tasks efficiently, but they struggle with complex problem-solving. In areas where robots fall short, human intervention becomes necessary. Reflecting on these challenges can guide further advancements in robotic optimization. The goal is a seamless interaction between human insights and machine performance.

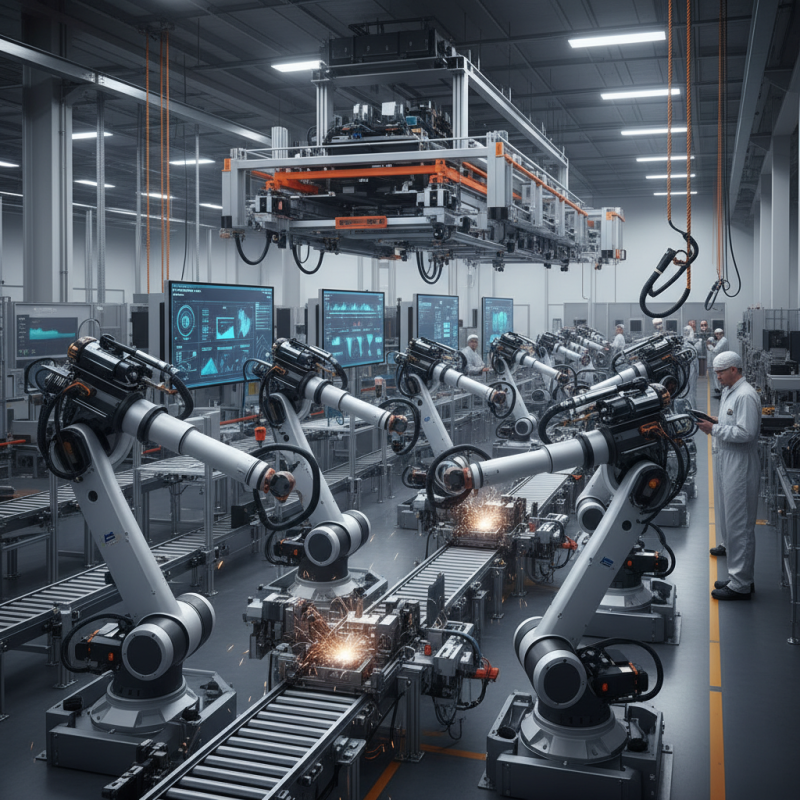

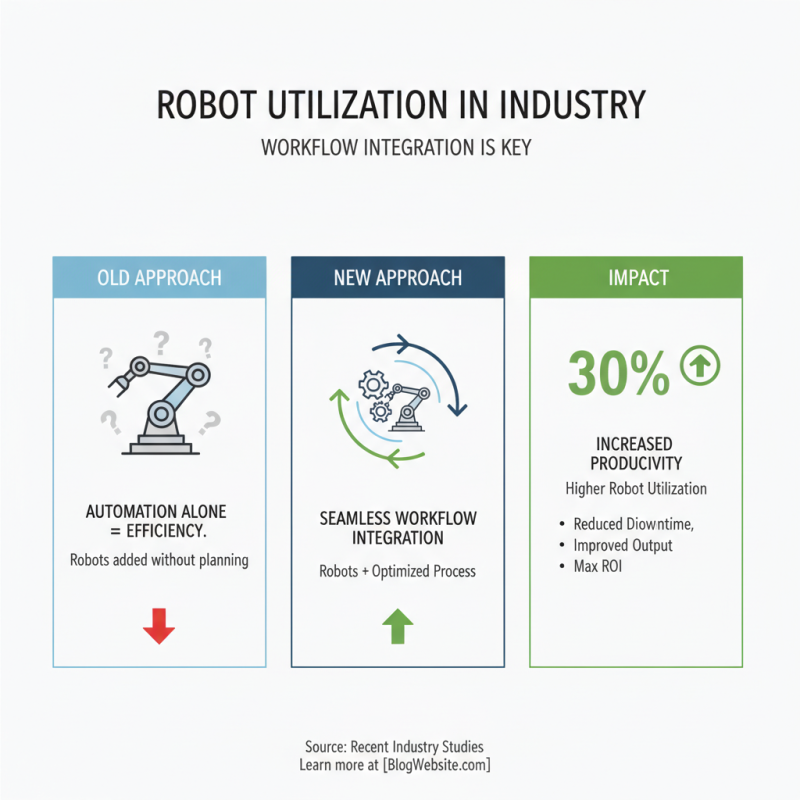

Evaluating workflow integration significantly impacts robot utilization rates in industrial settings. Recent studies indicate that effectively integrating robots into existing workflows can increase productivity by up to 30%. However, many companies overlook the importance of seamless integration, leading to underutilized robotic systems. Automation alone does not guarantee efficiency.

Some robots may sit idle, partly due to misaligned processes. For instance, if a robot is programmed for a specific task but the surrounding workflow is not optimized, the robot could operate below capacity. Research shows that nearly 20% of robotic systems are underperforming due to workflow disjointedness. Organizations need to analyze task flows critically to ensure robots maximize their potential.

Moreover, proper training for staff remains crucial. Employees must understand both the technology and how to incorporate it into their daily tasks. A lack of training can lead to resistance. Some workers may feel threatened by automation, reducing collaboration. Striking a balance between human roles and robotic capabilities is essential. An attentive evaluation of integration practices can lead to substantial improvements in operational efficiency, yet many still struggle with this adjustment.

Data analytics plays a pivotal role in optimizing industrial robotic systems. By harnessing actionable insights, companies can enhance robotic efficiency significantly. According to McKinsey, companies that implement data analytics can improve productivity by up to 30%. This transformation is crucial in the rapidly evolving manufacturing landscape.

To effectively leverage data analytics, start by collecting relevant performance metrics. Monitor cycle times, error rates, and maintenance schedules consistently. Analyze this data to identify patterns. For instance, specific tasks may require more time during peak hours. Adjusting schedules or reallocating robots can mitigate these issues.

Tips: Regularly update your data analytics tools. Invest in training for staff to interpret data correctly. Creating a culture of continuous improvement is vital. Engage your team in discussions about findings. Reflection can lead to innovative solutions. When mistakes happen, deeply analyze them. Each setback provides a chance for growth and reconfiguration of robotic processes. This restructures operations, often leading to remarkable efficiency boosts.