- sale@instructrobot.com

- Dallas, TX , United States

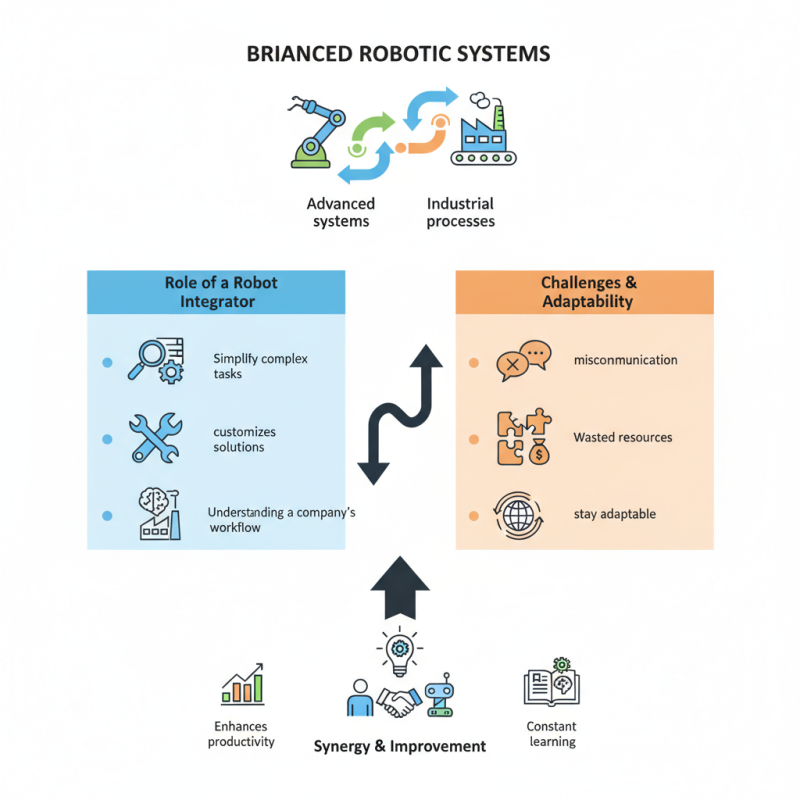

In the evolving landscape of automation, the role of a robot integrator becomes crucial. These professionals are the bridge between advanced robotic systems and industrial processes. They simplify complex tasks, making automation more accessible. A robot integrator customizes solutions based on specific needs. Their work often involves understanding a company’s workflow fully.

However, the integration process is not without challenges. Miscommunication can lead to ineffective solutions. Incorrect assessments of a company’s needs can result in wasted resources. It requires ongoing reflections and adjustments. Robot integrators must stay adaptable in a rapidly changing market. They deal with diverse systems and technologies daily, which can sometimes create friction.

The robot integrator acts as a guide on this journey. Their expertise enhances productivity, but constant learning is vital. Companies must invest time in this collaboration. Successful automation depends on the synergy between technology and human insight. Recognizing areas for improvement can lead to greater achievements.

A robot integrator plays a vital role in the automation landscape. They specialize in the integration of robotic systems into existing workflows. This process is not as simple as it sounds. It requires a deep understanding of both robotics and the specific industry needs.

Robot integrators evaluate the production line. They assess where robots can streamline tasks and improve efficiency. Their expertise helps to identify the right technology for each situation. However, integration can be challenging. Not all robotic solutions fit every application perfectly. Sometimes the transition leads to unexpected issues. It's crucial to adapt and refine the approach to ensure success.

In addition to technical skills, robot integrators must communicate well with teams. They need to understand the concerns of workers who fear job loss. Educating staff about the benefits of automation is essential. Without clear communication, the integration process can face resistance. This emphasizes the importance of building trust and collaboration among all stakeholders.

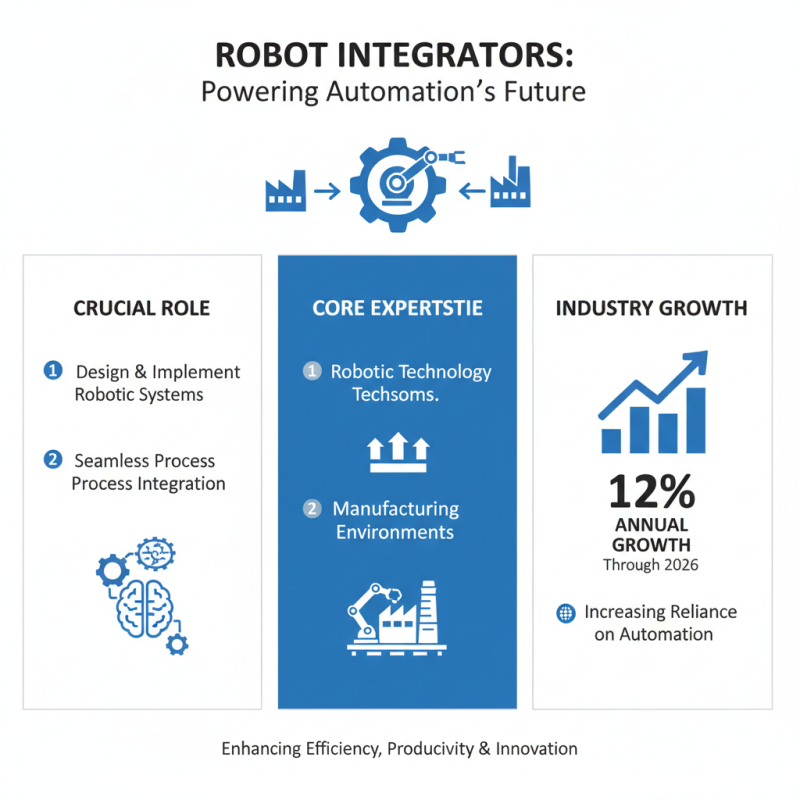

Robot integrators play a crucial role in enhancing automation across industries. Their main responsibility is to design and implement robotic systems that integrate seamlessly with existing processes. This requires a deep understanding of both robotic technology and the specific manufacturing environment. According to industry reports, the demand for robotic integration services is expected to grow by 12% annually through 2026, highlighting the increasing reliance on automation.

Key responsibilities of a robot integrator include system design, programming, and testing. They assess the workspace to ensure optimal robot placement. Effective communication with the workforce is essential for a smooth transition. Training staff to operate and maintain the robots is also part of the job. By fostering collaboration, integrators can enhance both safety and productivity.

Tips: Always consider the layout of the workspace. Inefficient setups can hinder robot performance. Regularly reviewing system efficiency helps identify areas for improvement. Seek feedback from operators about the robots' functionality. This input is invaluable for ongoing enhancements. Operators often have insights that data alone can't reveal. Engaging them leads to a more efficient automation process.

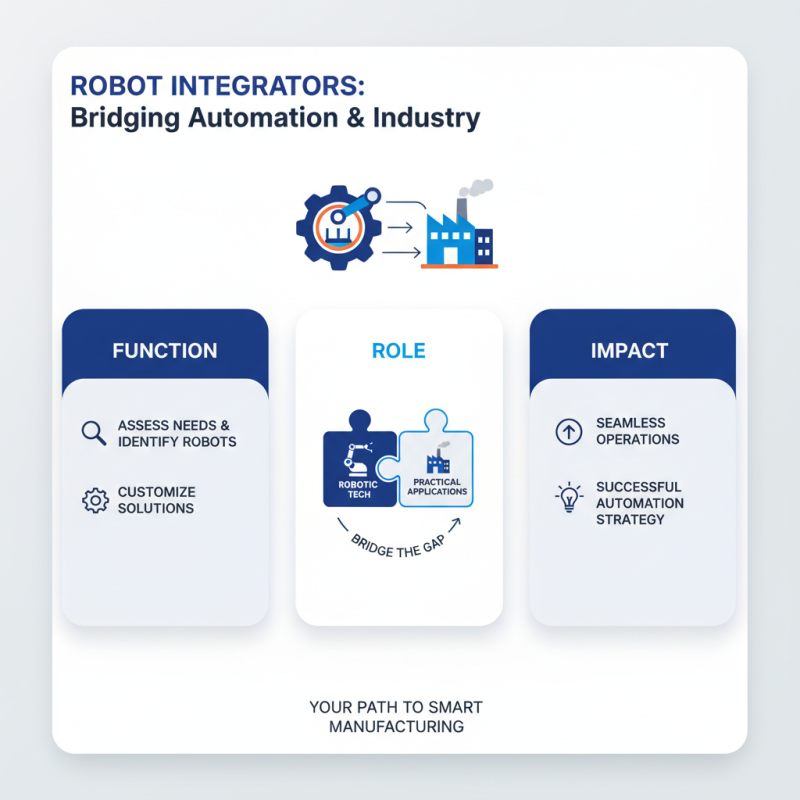

Robot integrators play a crucial role in automation projects. They bridge the gap between robotic technologies and practical applications in industries. Understanding their function can lead to a successful automation strategy. Integrators assess specific needs and identify suitable robots. They customize solutions to fit existing workflows, which is essential for seamless operations.

These professionals ensure that robots effectively communicate with other systems. They may face challenges during integration, like compatibility issues. Overcoming these hurdles requires creativity and problem-solving skills. Their expertise helps streamline processes, enhancing productivity and efficiency. Yet, not all projects go as planned. Regular feedback and adjustments are vital to optimize operations continuously.

Robot integrators also provide ongoing support after installation. They train staff to operate and maintain the systems effectively. Sometimes, employees may resist changes in workflow. Addressing these concerns through training can improve acceptance. The role of robot integrators in automation is dynamic and multifaceted, demanding adaptability and open communication throughout the project lifecycle.

Robot integrators play a crucial role in the automation landscape. Their work enhances operational efficiency across various industries. Yet, these integrators face unique challenges during implementation. A report from the International Federation of Robotics highlights that automation can improve productivity by up to 30%. However, achieving those gains is often complex.

One significant challenge is the integration of different robotic systems. Each robot comes with its own specifications and requirements. This variability can create compatibility issues. According to industry surveys, nearly 40% of automation projects experience delays due to integration complexities. Lack of standardized protocols often leads to confusion and escalated costs.

Tip: To mitigate these challenges, conduct thorough research on technology compatibility before starting.

Another challenge is the need for a skilled workforce. As robotics technology evolves, many technicians lack the necessary knowledge. This skills gap can slow down implementation. A report from McKinsey suggests that by 2030, up to 85 million jobs may be displaced by automation. Invest in training programs to upskill existing employees.

Tip: Partner with educational institutions to create a talent pipeline.

In conclusion, while robot integrators enhance automation, they must navigate various hurdles. The key lies in recognizing these challenges and proactively addressing them.

Robot integrators are key players in enhancing automation for businesses. They design and implement robotic systems that streamline processes. These experts ensure that robots work seamlessly with existing systems. This reduces downtime and improves efficiency, which is crucial in today's fast-paced market.

Using robot integrators offers various advantages. They tailor solutions to specific needs, which saves time and resources. Businesses can optimize their workflows and allocate labor more effectively. By automating repetitive tasks, companies can focus on more complex projects. However, not all integrations are flawless; sometimes the technology doesn’t align perfectly with existing operations, leading to hiccups in implementation. These challenges need careful consideration and ongoing evaluation.

Moreover, the financial aspect is vital. Investing in robotic integration can seem daunting. Yet, the long-term savings and potential for growth often outweigh initial costs. Balancing the immediate financial impact with future gains is essential for making informed decisions. As businesses navigate these choices, having skilled integrators by their side is increasingly important.

| Dimension | Description | Example Benefit |

|---|---|---|

| Customization | Robot integrators tailor automation solutions to fit specific business needs. | Improved efficiency as solutions are aligned with workflows. |

| Expertise | Combining knowledge in robotics and system integration. | Reduced risks in the implementation of automation technologies. |

| Support and Maintenance | Ongoing support and maintenance services. | Maximized uptime and performance of robotic systems. |

| Integration Capability | Ability to integrate multiple technologies and systems. | Streamlined operations through cohesive functioning of systems. |

| Cost Reduction | Optimizing processes to lower operational costs. | Increased profitability through cost-effective automation. |