- sale@instructrobot.com

- Dallas, TX , United States

Soft robotics is an emerging field that lies at the intersection of engineering and biology, characterized by the development of robots made from highly flexible materials that can mimic the adaptability of living organisms. These innovative machines are designed to perform tasks that conventional rigid robots struggle with, particularly in unpredictable environments or when interacting with delicate objects. As a result, soft robotics is not only revolutionizing traditional manufacturing and automation processes but also opening up new avenues in healthcare, agriculture, and even space exploration.

The transformative potential of soft robotics is already becoming evident in various sectors. From soft robotic grippers capable of handling fragile items like fruits and glassware to bio-inspired robots that can traverse complex terrains, the flexibility and tunability of these systems offer unprecedented advantages. In healthcare, researchers are developing soft robotic devices that can assist in surgeries or provide rehabilitation support, enhancing patient care and outcomes. By exploring the top five advancements in this fascinating field, we can better understand how soft robotics is reshaping technology today, paving the way for a more adaptable and efficient future.

Soft robotics is an emerging field that prioritizes compliance and adaptability in robotic design. Unlike traditional rigid robotics, which relies on fixed structures, soft robots are constructed using flexible materials that can emulate natural movements. This adaptability is primarily achieved through the use of polymers, elastomers, and other soft materials, which allow the robots to deform and conform to various shapes and environments. The underlying principles of soft robotics are inspired by biological organisms, enabling robots to interact with delicate objects and navigate complex environments with greater ease.

The materials used in soft robotics play a crucial role in its functionality and versatility. Silicone elastomers, hydrogels, and soft composites are commonly employed due to their ability to undergo significant deformation while maintaining structural integrity. These materials can also be embedded with sensors and actuators, enabling soft robots to perform a range of tasks from surgical assistance to exploration in hazardous environments. As research progresses, the integration of advanced materials such as shape-memory alloys and conductive polymers is paving the way for smart soft robots that can respond dynamically to their surroundings, further enhancing their potential applications in various industries.

Soft robotics is an innovative field emerging at the intersection of robotics and materials science. This technology employs flexible materials, enabling robots to mimic the adaptability seen in biological organisms. Key innovations in soft robotics are revolutionizing various industries, particularly in healthcare and manufacturing. According to a report by Research and Markets, the global soft robotics market is projected to reach $1.68 billion by 2026, growing at a CAGR of 39.5% from 2021. Such rapid growth is attributed to the increasing need for patient-friendly robotic systems in medical applications.

In healthcare, soft robots are enhancing surgical precision and rehabilitation processes. For instance, soft robotic gloves are being utilized to assist stroke patients in regaining motor functions, demonstrating their potential in therapeutic settings. Meanwhile, the manufacturing sector benefits from soft robotics through enhanced automation, with soft grippers capable of handling delicate items without damaging them. A study published in the IEEE Robotics and Automation Magazine highlights a significant reduction in handling errors and increased efficiency, indicating that businesses are swiftly adopting soft robotic solutions to streamline operations and reduce waste. These advancements reveal that soft robotics is not just a technological novelty but a transformative force across various sectors.

| Application Area | Key Innovations | Impact on Industry |

|---|---|---|

| Medical Devices | Soft robotic grippers for delicate surgeries | Increased precision and reduced patient recovery time |

| Agriculture | Soft actuators for harvesting fruits | Higher yield with minimal damage to crops |

| Underwater Exploration | Soft robotics for deep-sea manipulation | Improved ability to explore and collect samples without disturbing environments |

| Manufacturing | Flexible robotic arms for assembly | Enhanced efficiency and flexibility in production processes |

| Consumer Electronics | Adaptive robotic assistants | Improved user interaction and personalized services |

Soft robotics is rapidly gaining traction in the fields of healthcare and rehabilitation, showcasing its unique advantages over traditional rigid robotic systems. Designed to mimic the pliability and adaptability of biological organisms, soft robots can interact safely and effectively with humans. This characteristic is particularly beneficial in therapeutic settings, where gentle and adaptable assistance is crucial for patient safety and comfort.

In healthcare, soft robotic devices are employed in various applications, from aiding in physical therapy to providing enhanced mobility solutions for individuals with disabilities. For instance, soft exoskeletons can deliver support during rehabilitation exercises, promoting gradual recovery while minimizing the risk of injury. Additionally, these robots can assist in tasks such as lifting and transferring patients, significantly reducing the physical strain on caregivers. With ongoing advancements in material science and robotic design, the integration of soft robotics into medical practices is expected to enhance patient outcomes and revolutionize the way rehabilitation is approached.

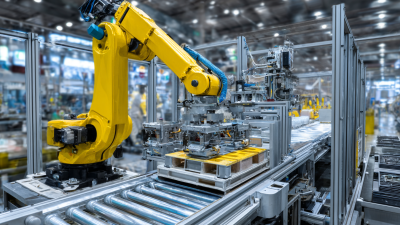

Soft robotics is rapidly transforming the landscape of automation and manufacturing. Utilizing compliant materials, soft robots offer versatility and safety in unstructured environments where traditional rigid robots may struggle. According to a report by Research and Markets, the global soft robotics market is projected to reach $1.6 billion by 2028, driven by advancements in technology and increasing demand from industries such as healthcare, logistics, and food processing.

In manufacturing, soft robotics enhances operational efficiency by enabling delicate handling of products, which is crucial for tasks that require precision—like assembling electronics or packaging fragile items. A 2022 study highlighted that companies adopting soft robotic systems experienced a 30% increase in productivity due to reduced downtime and fewer damages during handling. Such adaptable solutions not only simplify processes but also minimize workplace injuries, fostering a safer work environment.

**Tips for Implementing Soft Robotics in Your Operations:** Start by assessing specific operational challenges where soft robots could provide advantages. Conduct pilot tests with various soft robotic systems to understand their potential control mechanisms and compatibility with existing workflows. Investing in training for personnel will further ease the integration, ensuring that your workforce is well-equipped to maximize the benefits of these innovative technologies.

Soft robotics is an emerging field that leverages flexible materials to create robots capable of safe interaction with humans and delicate environments. As technology progresses, several key trends are shaping the future of soft robotics, highlighting both challenges and opportunities. One significant trend is the integration of artificial intelligence, which enhances the adaptability and functionality of soft robots. This combination enables robots to learn from their interactions and improve over time, making them more useful in diverse applications ranging from healthcare to agriculture.

However, the advancement of soft robotics is not without hurdles. Researchers face challenges in material durability, control systems, and the scalability of manufacturing processes. Developing robust materials that maintain flexibility while being resistant to wear and environmental factors remains a critical area of innovation. Nevertheless, these challenges present opportunities for collaboration across disciplines, fostering advancements in material science, electronics, and machine learning. As the field continues to evolve, the potential for soft robotics to revolutionize industries and improve quality of life becomes increasingly tangible.