- sale@instructrobot.com

- Dallas, TX , United States

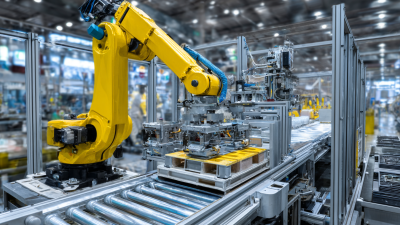

In today's fast-paced manufacturing environment, a robot palletizer can significantly enhance efficiency. Many businesses face challenges in selecting the right robot palletizer. The wrong choice can lead to productivity loss and increased costs.

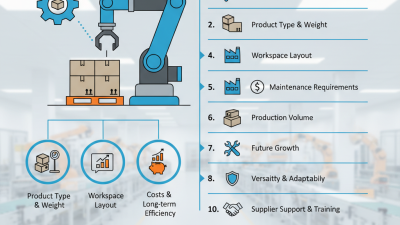

Understanding your specific needs is crucial. Each operation has unique requirements based on product type, weight, and size. A robot palletizer suited for one factory may not be ideal for another. For instance, a high-speed line may demand a more advanced model, while a smaller operation might benefit from a basic robot.

Potential buyers should also consider future scalability. As your business grows, so do your needs. Investing in a flexible robot palletizer can save you time and money later. Take the time to reflect on these aspects before making a decision. Choosing wisely can transform your operations for the better.

Choosing a robot palletizer requires careful consideration of various factors. First, assess your production needs. Understand the types of products you'll be handling. Consider their weight, size, and shape. This knowledge will guide your selection. A versatile robot can manage different products. You might need a more specific solution for unique items.

Next, think about your workspace. Measure your facility's layout. Ensure the robot fits comfortably in your environment. Safety is also crucial. Consider how the palletizer will interact with human staff. Create a safe working zone where collisions are minimized. Experts often overlook this aspect. It can lead to costly mistakes later on.

Another crucial factor is scalability. Your business may grow or change. Choose a palletizer that can adapt to new demands. A system that can be upgraded is often more beneficial. However, remember that technology evolves quickly. What seems perfect today might need adjustments tomorrow. Keep this in mind when making your decision.

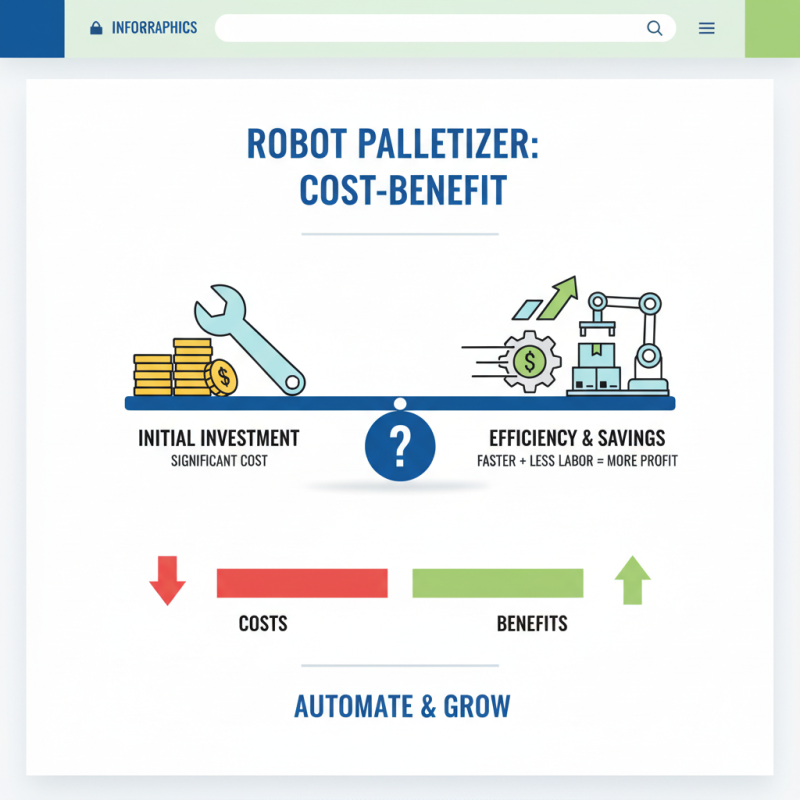

When considering a robot palletizer, understanding the cost-benefit analysis is crucial. A robot palletizer can automate stacking, increasing efficiency. Higher efficiency means faster operation and reduced labor costs. However, the initial investment is significant. Businesses need to weigh these costs against potential savings.

Maintenance is another factor. Regular upkeep is necessary to avoid unexpected breakdowns. This can add to expenses and impact the bottom line. Additionally, specialized training for staff may be required. Some companies overlook this when calculating their budget.

Not every operation is suited for automation. Complexity can affect the effectiveness of robot palletizers. They may not adapt well to varying product sizes or shapes. It’s important to reflect on your specific needs and processes. A thorough evaluation can help determine if this investment is worthwhile.

When evaluating robot palletizing solutions, throughput and efficiency metrics are critical. Industry reports indicate that automation can boost productivity by up to 30%. This significant increase stems from the ability of robots to operate continuously, reducing downtime. An efficient robot palletizer can handle over 1,200 cycles per hour, depending on the product and setup.

Efficiency metrics such as cycle time and payload capacity should be closely examined. For example, robots designed for high-speed applications may prioritize speed over versatility. A system that can handle diverse payloads might sacrifice speed for adaptability. It’s crucial to align these metrics with specific operational goals. The right choice often requires careful analysis of your workflow.

Consider integration challenges as well. Not all systems adapt seamlessly to existing infrastructure. The right robot should complement your current operations, not complicate them. Reports highlight that poorly integrated systems can lead to reduced overall efficiency. This underscores the need for thoughtful planning and evaluation before making a decision.

| Feature | Description | Metric | Typical Range |

|---|---|---|---|

| Throughput | The number of units processed per hour. | Units per hour | 500-3000 |

| Payload Capacity | Maximum weight the robot can handle. | Kilograms | 50-200 |

| Speed | Rate at which the robot operates. | Cycles per minute | 10-30 |

| Flexibility | Ability to handle different products and configurations. | Number of configurations | 1-10+ |

| Energy Consumption | Amount of power used during operation. | kWh per hour | 1-5 |

| Safety Features | Built-in systems to prevent accidents. | Number of safety protocols | 1-10 |

Choosing the right robot palletizer involves evaluating its flexibility and compatibility with your products. Different industries have unique requirements. A palletizer must adapt to various item shapes and sizes. Some systems excel in handling cases, while others manage bags or bulk products. Assessing these needs is crucial.

Compatibility with existing equipment is also vital. You want a robot palletizer that integrates smoothly with your conveyor systems and packaging lines. Compatibility reduces downtime and maintenance costs. Flexibility to handle multiple products can enhance operational efficiency. However, some robot models may struggle with diverse product types.

Testing the robot's performance with your products is essential. Sometimes, a robot that looks good on paper may not meet real-world demands. There may be issues with speed or precision. Design a trial run to evaluate if it handles your products smoothly. Reflection on these trials provides insights for better decisions. Keep in mind that the best option for one business might not be the same for yours.

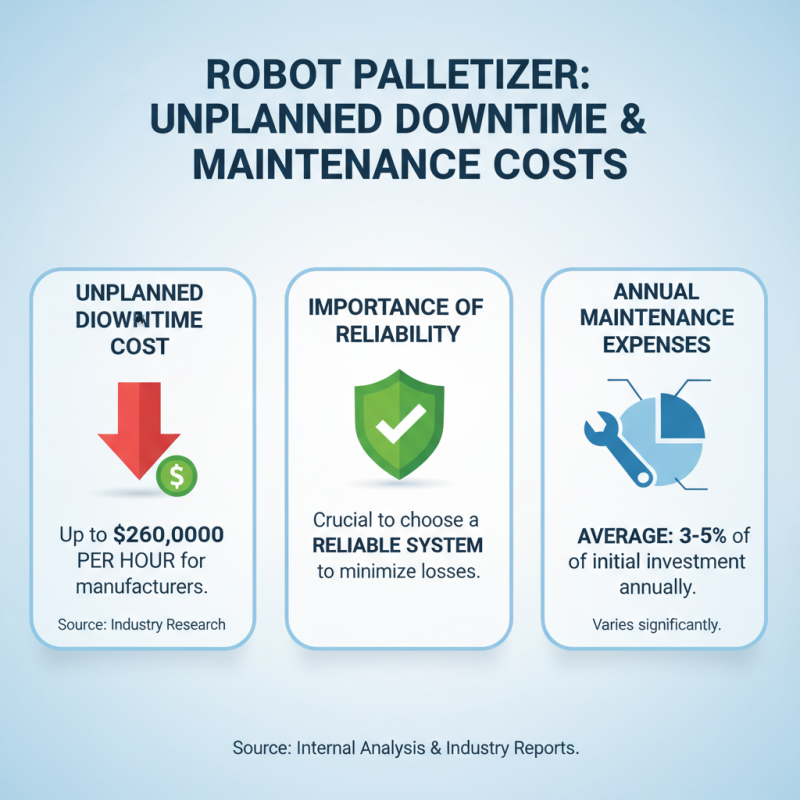

When selecting a robot palletizer, analyzing maintenance costs and downtime is vital. Research shows that unplanned downtime can cost manufacturers up to $260,000 per hour. This figure underscores how crucial it is to choose a reliable system. Maintenance expenses can also vary significantly. On average, companies spend about 3-5% of the initial investment on maintenance annually.

Tips for evaluating maintenance costs include looking at the service agreements carefully. Consider options that provide comprehensive support. It can help mitigate unexpected expenses. Downtime impacts can be minimized through regular maintenance schedules. Implementing predictive maintenance can reduce unexpected failures and improve overall efficiency.

Another important factor is the training of staff. An investment in employee training can significantly reduce the likelihood of operational errors. Poorly trained staff can lead to equipment misuse, which often results in increased downtime and higher costs. Balancing initial investment with potential hidden costs is essential for optimizing ROI. Regular assessment of performance metrics is crucial to ensure the palletizer meets business needs efficiently.