- sale@instructrobot.com

- Dallas, TX , United States

As the manufacturing landscape evolves, the integration of advanced technologies has become indispensable. Among these innovations, industrial robots play a pivotal role in transforming production processes. According to Dr. Sarah Thompson, a leading expert in robotics and automation, "The future of manufacturing is wired with intelligent machines that redefine efficiency and precision." This insight underscores the critical impact of industrial robots in enhancing productivity and flexibility in various sectors.

In 2023, a myriad of industrial robots is set to revolutionize the way industries operate. From assembly lines to quality control, these machines are not only streamlining tasks but also enabling manufacturers to respond swiftly to changing market demands. The capabilities of industrial robots have expanded beyond basic repetitive tasks, incorporating advanced features such as artificial intelligence and machine learning, which allow for adaptive and smart manufacturing solutions.

As we delve into the top 10 industrial robots transforming manufacturing this year, it is clear that these technologies are not merely tools but strategic partners in driving innovation and competitiveness. The adoption of industrial robots marks a significant step towards achieving higher operational standards and sustainable growth in the ever-demanding manufacturing arena.

The evolution of industrial robots in manufacturing has marked a significant shift in operational efficiencies, enhancing productivity and reducing costs across various sectors. According to a report by the International Federation of Robotics, the global stock of operational industrial robots reached over 3 million units in 2022, with expectations for continued exponential growth as industries increasingly adopt automation technologies. The integration of advanced artificial intelligence and machine learning algorithms into robotics has enabled these machines to perform complex tasks with higher precision, adaptability, and speed, paving the way for smarter factories.

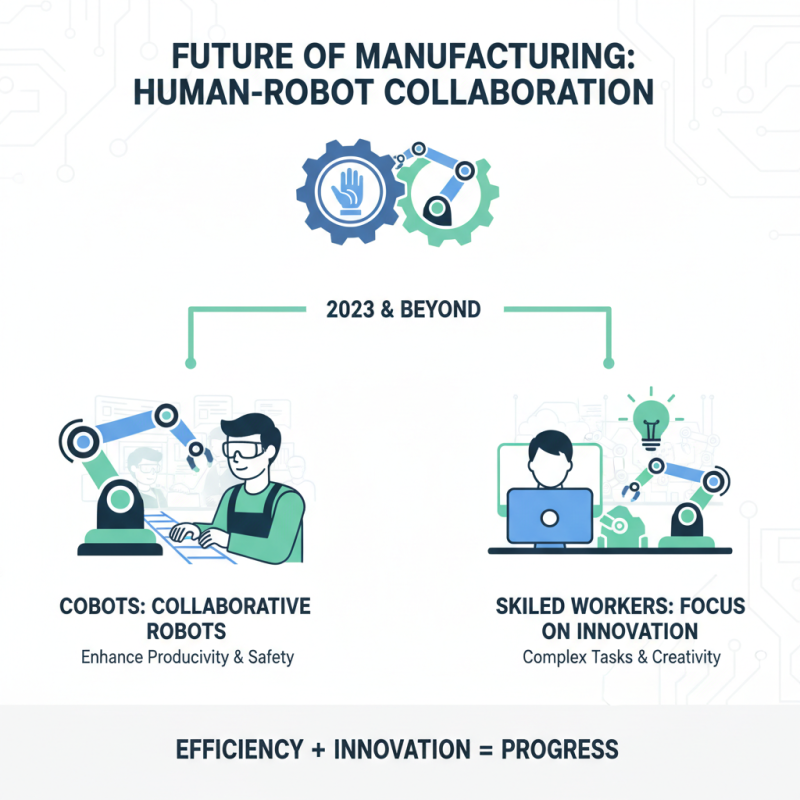

Furthermore, collaborative robots, or cobots, have emerged as a transformative force in the manufacturing landscape. Unlike traditional industrial robots that operate in isolation, cobots work alongside human operators, enhancing safety and efficiency. A recent market analysis indicated that the collaborative robot market is projected to expand at a compound annual growth rate (CAGR) of 45% between 2023 and 2028, signifying a robust demand for flexible automation solutions. As manufacturing systems become increasingly digitized and interconnected, the role of industrial robots is set to become more ingrained in the operational fabric, driving innovation and fostering competitiveness in a rapidly evolving manufacturing environment.

| Robot Model | Type | Payload Capacity (kg) | Reach (m) | Applications |

|---|---|---|---|---|

| Model A1 | Articulated | 10 | 1.5 | Welding, Assembly |

| Model B2 | Collaborative | 8 | 1.2 | Packaging, Sorting |

| Model C3 | Delta | 4 | 0.8 | Pick and Place |

| Model D4 | SCARA | 6 | 1.0 | Assembly, Inspection |

| Model E5 | Cartesian | 12 | 2.0 | Material Handling |

| Model F6 | Mobile | 15 | 1.5 | Transport, Delivery |

| Model G7 | Humanoid | 5 | 1.6 | Customer Interaction |

| Model H8 | Articulated | 25 | 2.5 | Heavy Duty Tasks |

| Model I9 | Collaborative | 10 | 1.3 | Assisting Workers |

| Model J10 | Cartesian | 20 | 2.2 | Assembly, Inspection |

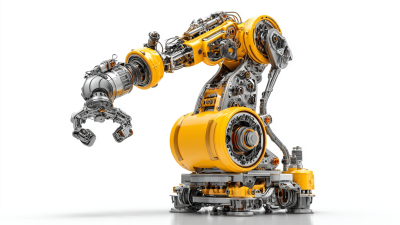

The manufacturing landscape in 2023 has been significantly reshaped by advanced industrial robots, harnessing cutting-edge technology to enhance productivity, precision, and safety. These robots come with an array of key features that make them indispensable in various production environments. With capabilities such as AI-powered vision systems, collaborative functions for working alongside humans, and adaptive learning algorithms, these robots can efficiently handle tasks ranging from assembly to quality control. According to a recent report by International Federation of Robotics, global sales of industrial robots increased by 22% in 2022, highlighting the critical role they play in modern manufacturing.

As companies strive for greater flexibility and efficiency, many of the top industrial robots of 2023 are designed with modular architectures and interoperability in mind. This allows manufacturers to seamlessly integrate robots into existing workflows. Additionally, advancements in sensor technology enable real-time data collection, allowing for predictive maintenance and minimizing downtime. Furthermore, the emphasis on energy efficiency in robotic design aligns with the growing importance of sustainability in manufacturing, as highlighted by a McKinsey report indicating that energy consumption in manufacturing is projected to rise by 30% by 2030 if unaddressed.

Tip: When considering the integration of industrial robots, it is crucial to conduct a thorough assessment of your production line to identify specific areas where automation can provide the most value. Investing in training for human workers to effectively collaborate with these robots can also enhance overall efficiency. Additionally, keeping abreast of emerging trends and technologies in robotics can position your company for long-term success in an increasingly competitive market.

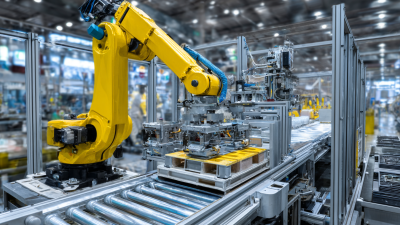

In 2023, the industrial sector is experiencing a significant transformation, driven by advancements in robotics technology. Leading industrial robots are now being applied across various industry sectors, showcasing their versatility and capability to enhance production efficiency. One notable application is in the automotive industry, where robots are employed for assembly line tasks, precision welding, and paint applications. These robots ensure high-quality standards while maintaining speed, reducing the need for human intervention in hazardous environments.

Additionally, the electronics sector is witnessing the integration of agile robotics for tasks such as component assembly and quality control. Robots equipped with advanced vision systems can detect defects in real-time, ensuring that only flawless products move to the next production stage. Moreover, the food and beverage industry benefits from robots that automate packing and palletizing processes, which not only increases output but also ensures hygiene and consistency in product handling.

Overall, the application of industrial robots across these sectors is redefining manufacturing processes, leading to increased productivity and reduced operational costs.

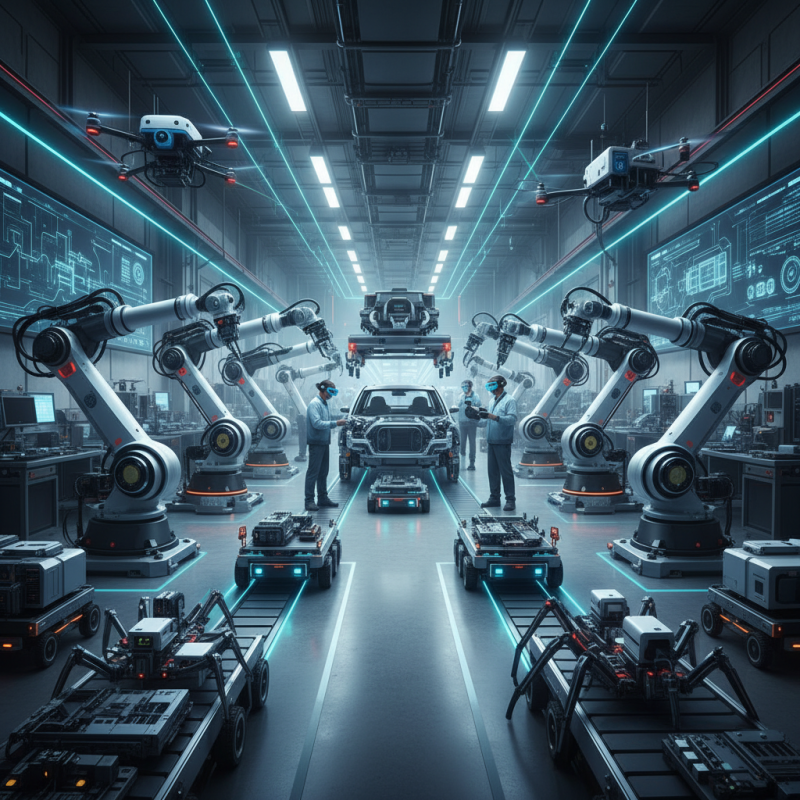

The integration of industrial robots into manufacturing processes is significantly enhancing efficiency and productivity while reshaping the workforce landscape. Automation allows for more precise and consistent production, reducing the likelihood of human error and increasing output. Robots can handle repetitive and physically demanding tasks, which not only accelerates production cycles but also frees up human workers to engage in higher-value activities. This shift towards automation enables manufacturers to optimize their operations and maintain a competitive edge in an increasingly globalized market.

However, the impact of automation on the workforce cannot be overlooked. As robots take on more functions, the demand for low-skill labor may decline, leading to concerns about job displacement. To address these challenges, companies need to invest in retraining and upskilling their employees. This transition offers a unique opportunity for the workforce to evolve, as individuals can learn to work alongside robots and enhance their skills in areas like programming, maintenance, and data analysis. Ultimately, effective automation strategies that prioritize reskilling will help create a more adaptable workforce prepared for the future of manufacturing.

The integration of industrial robotics in manufacturing is poised to reshape the landscape of production processes in 2023 and beyond. One of the most significant trends is the growing application of collaborative robots, or cobots, which are designed to work alongside human operators. This synergy not only enhances productivity but also promotes a safer working environment. Manufacturers are increasingly investing in cobots to handle repetitive tasks, allowing skilled workers to focus on more complex and creative responsibilities. This trend underscores the importance of human-robot collaboration as a key driver of efficiency and innovation in manufacturing.

Moreover, advancements in artificial intelligence and machine learning are facilitating smarter robotic systems capable of adaptive learning. These intelligent robots can analyze their surroundings, optimize workflows, and make real-time decisions, leading to more streamlined operations. The ability to integrate seamlessly with existing manufacturing systems is critical for achieving higher levels of automation and flexibility. As industries begin to recognize the potential of data-driven robotics, the synergy between robotics and manufacturing will foster enhanced precision, reduced waste, and improved quality control, paving the way for the factories of the future.