- sale@instructrobot.com

- Dallas, TX , United States

In today's fast-paced manufacturing and logistics environments, robotic palletizing systems have become essential for enhancing efficiency and productivity. As companies strive to optimize their operations, the need for reliable and versatile palletizing solutions has never been greater. With the rapid advancement of automation technology, selecting the right robotic palletizing system can be a daunting task. Various factors must be considered, including the specific requirements of the product being handled, the layout of the workspace, and the overall goals for automation.

This guide presents the top 10 tips for choosing the best robotic palletizing systems to meet your needs. By understanding key aspects such as payload capacity, adaptability to different product types, ease of integration, and maintenance requirements, businesses can make informed decisions that align with their operational strategies. As you navigate through these considerations, you'll be better equipped to assess available options and implement a system that not only increases productivity but also enhances the return on your investment in automation technology. Emphasizing these critical factors will empower you to select a robotic palletizing solution that supports your company's growth for years to come.

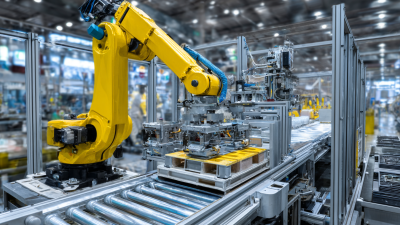

Robotic palletizing systems have revolutionized the logistics and manufacturing industries by improving efficiency and reducing labor costs. These systems automate the process of stacking products onto pallets, allowing for quicker and more accurate handling of goods. Understanding the fundamental components and functionalities of robotic palletizing systems is essential for businesses looking to optimize their operations. Typically, these systems consist of robotic arms, end-of-arm tooling, and software that coordinates the movement and placement of products.

When choosing a robotic palletizing system, it’s crucial to assess the specific needs of your operations. One key tip is to evaluate the types of products being handled. Different payloads and dimensions may require specialized end-of-arm tooling to ensure proper handling. Additionally, consider the speed and throughput requirements of your production line. Systems that can adapt to varying speeds may offer greater flexibility as production demands change.

Another important factor is the ease of integration with existing equipment. Look for systems that can seamlessly connect with your current conveyor belts and machinery to minimize disruptions during installation. Moreover, ensure that the system you are considering has strong support and user-friendly software, which will facilitate ease of use and maintenance. By keeping these tips in mind, businesses can make informed decisions when selecting the optimal robotic palletizing solution to enhance their operational efficiency.

This chart illustrates the importance of various factors when selecting robotic palletizing systems based on industry surveys.

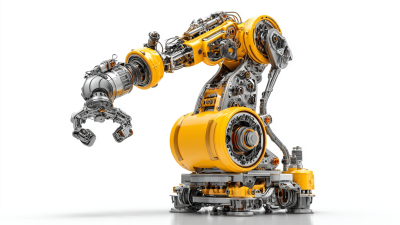

When selecting a robotic palletizer, several key features are essential to ensure optimal performance and efficiency. Firstly, consider the payload capacity of the robotic arm. It is crucial that the chosen system can handle the weight and size of the products being stacked. This specification determines the type of goods the palletizer can effectively manage and influences the overall operational throughput. Additionally, the reach and flexibility of the robot are vital; a robotic system with an extended reach can cover larger areas, making it adaptable to varied configurations within a warehouse or production line.

Another important feature is the speed and cycle time of the robotic palletizer. Systems that can operate at higher speeds will enhance productivity, minimizing downtime and maximizing output. Look for models that offer customizable settings for different speeds to accommodate various product types and operations. Furthermore, consider the ease of integration with existing equipment and systems, such as conveyor belts or pick-and-place systems. A user-friendly interface for programming and adjustments is also an essential aspect, allowing operators to quickly adapt the machinery to changing production needs while ensuring minimal disruption to workflow.

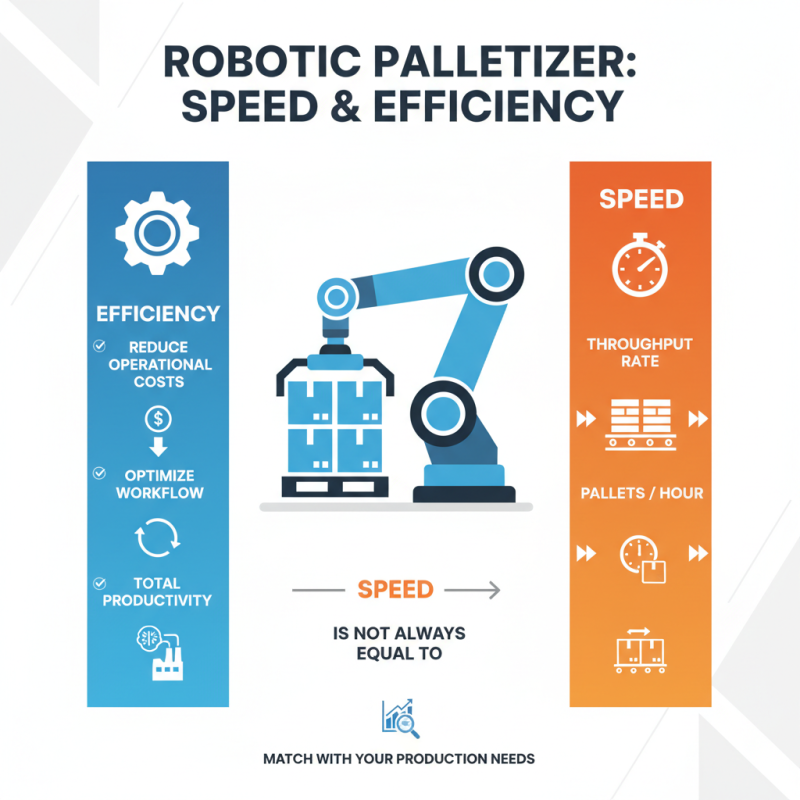

When selecting a robotic palletizing system, assessing the efficiency and speed is critical. Efficient systems can significantly reduce operational costs and optimize workflow. Start by evaluating the throughput rate of various robots, which is a measure of how many pallets they can handle per hour. This rate varies among systems, so it's essential to match it with your production needs. Higher speed doesn't always equate to better efficiency; consider the overall productivity in your application context.

Another important consideration is the adaptability of the system to various load types and sizes. A versatile robotic palletizer can manage different products without extensive reprogramming. This flexibility allows for smoother transitions between products and can enhance overall efficiency. Investing in a system that can easily adjust to different palletizing patterns can further improve your speed and output.

Integrate the insights from real-world applications and case studies to see how different systems perform under specific conditions. Looking into user experiences can provide valuable information about the long-term reliability and maintenance needs of the robotic palletizers. Efficiency and speed in robotic systems are not solely defined by numbers; the integration into your operational environment plays a crucial role in maximizing their effectiveness.

When considering robotic palletizing systems, evaluating cost and return on investment (ROI) is crucial for making informed decisions. The initial outlay for these systems can be significant, which means understanding how to assess their value in relation to your operational needs is essential. Start by analyzing the expected productivity gains. A robotic palletizing system can streamline operations, reduce labor costs, and minimize errors, all of which contribute positively to your bottom line.

In addition to productivity, it's important to factor in longevity and maintenance costs. While the upfront investment is substantial, many systems are designed for durability, which can lead to lower maintenance expenses over time. Compare the operational lifespan of various options and consider whether their components are easily accessible for repairs. Another tip is to evaluate the system's flexibility in handling different products or adjusting to varying pallet patterns, which can impact overall efficiency and return.

When conducting a cost-benefit analysis, also remember to factor in the potential for scaling your operations in the future. A good robotic palletizing solution should not only meet your current needs but also adapt to your evolving requirements. By comprehensively assessing initial costs against these various factors, you can make more informed decisions that align with your business goals.

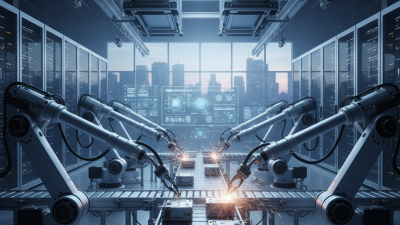

Integrating robotic systems into existing production lines can significantly enhance efficiency and streamline operations. One of the first considerations when integrating robotic palletizing systems is assessing the current workflow. Understanding the layout and flow of materials is crucial; this ensures that the robotic system is deployed effectively without disrupting existing processes. Conducting a thorough analysis of production line capabilities allows for tailored solutions that fit seamlessly into the existing system.

Additionally, the installation of robotic systems should prioritize flexibility and scalability. As production demands evolve, having a system that can adapt to changes—such as different product types or volumes—is essential. This means choosing a robotic palletizing solution that is compatible with various packaging sizes and configurations. Moreover, a gradual integration approach can help to minimize downtime. It’s advisable to start with pilot implementations to test the system's performance and make necessary adjustments, ensuring that the transition enhances productivity rather than hindering it. By carefully planning and testing the integration, companies can fully leverage the benefits of robotic systems.

| Tip Number | Tip Description | Considerations | Potential Benefits |

|---|---|---|---|

| 1 | Assess Production Needs | Analyze current production volume and type of products | Tailored solutions that optimize efficiency |

| 2 | Evaluate Robot Type | Consider articulated vs. gantry robots | Improved flexibility and adaptability |

| 3 | Consider Payload Capacity | Match robot's capacity to your heaviest product | Enhanced handling capability |

| 4 | Assess Total Cost of Ownership | Include maintenance and operational costs | Better budget management |

| 5 | Evaluate Software Compatibility | Integration with existing systems | Streamlined processes and data sharing |

| 6 | Seek Vendor Support and Training | Assess the level of support available post-installation | Increased operator confidence and skill |

| 7 | Consider Installation Requirements | Space, power, and network requirements | Smooth and timely installation process |

| 8 | Explore Scalability Options | Future expansion needs and upgrades | Long-term investment security |

| 9 | Review Safety Features | Compliance with safety standards | Minimized risk of accidents |

| 10 | Consider Customization Options | Flexibility to adapt to specific needs | Optimal performance tailored to processes |