- sale@instructrobot.com

- Dallas, TX , United States

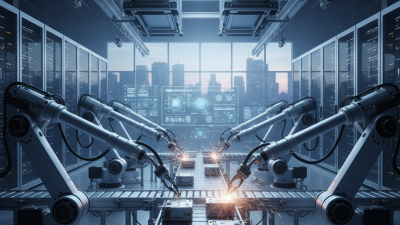

Investing in a robot palletizer can significantly enhance your production efficiency and streamline operations in your business. As automation continues to transform the manufacturing landscape, choosing the right robot palletizer tailored to your specific requirements is crucial. With numerous options available on the market, each with varying features and capabilities, businesses must navigate the decision-making process carefully to ensure optimal productivity and return on investment.

In this guide, we will explore the top 10 tips that will aid you in selecting the best robot palletizer for your unique business needs. From assessing the volume of materials to be handled to considering integration into existing systems, these insights aim to simplify the selection process. By focusing on the crucial aspects of efficiency, flexibility, and scalability, you can make an informed choice that will not only meet your current demands but will also adapt to future growth. Embracing automation with the right robot palletizer is an essential step towards achieving operational excellence and remaining competitive in today's fast-paced market.

When selecting a robot palletizer, it’s crucial to understand the various types available in the market. The primary categories include articulated arm palletizers, gantry palletizers, and collaborative robot (cobot) palletizers. According to a report by Markets and Markets, the automated palletizing market is projected to reach $3.3 billion by 2026, highlighting an increasing demand for efficiency and productivity in manufacturing processes. Articulated arm palletizers, known for their flexibility and ability to handle a wide variety of products, are ideal for industries with high throughput requirements. They typically offer six or more axes and excel in complex operations where precision is paramount.

In contrast, gantry palletizers are favored for their strength and speed, operating on a fixed structure to maximize throughput for larger loads. Their ability to stack heavy items efficiently makes them suitable for industries like beverage and food packaging. Meanwhile, the rise of collaborative robots offers smaller businesses a cost-effective and flexible alternative. A study by the International Federation of Robotics indicates that the adoption of cobots has surged by over 50% since 2019, reflecting a growing trend in embracing automation, even in smaller-scale operations. Understanding these distinctions is essential for choosing the best robot palletizer tailored to specific operational needs.

Choosing the best robot palletizer for your business requires a thorough assessment of your automation and efficiency needs. As industries increasingly adopt automation to enhance productivity, understanding the specific requirements of your operations is crucial.

Factors such as throughput, payload capacity, and the type of products being handled should guide your selection. Moreover, analyzing existing workflows to identify bottlenecks can help you determine how automation can be integrated effectively.

The global market for automation solutions, particularly in areas like warehouse management and manufacturing, is witnessing significant growth. For instance, the demand for lifecycle assessment software is projected to reach $695.3 million by 2032, growing at a compound annual growth rate (CAGR) of 15%. Similarly, the shift towards intelligent automation is evident in projections for the factory automation sector in Japan, which anticipates a CAGR of 14.78% from 2022 to 2032. As businesses invest in automation technologies, they must ensure that the chosen systems align with their needs for efficiency and scalability to remain competitive in a rapidly evolving marketplace.

When evaluating the technical specifications of robot palletizers, it’s crucial to consider factors such as payload capacity, speed, and flexibility. According to a report by MarketsandMarkets, the global robotic palletizing market is projected to reach USD 2.28 billion by 2026, emphasizing a growing demand for efficient packaging solutions. Businesses must assess payload capacity to ensure the robot can handle the weights of the products being stacked. For instance, some advanced models can support payloads of up to 2,500 pounds, making them suitable for heavier loads typical in industries like food and beverage.

Speed is another critical specification; many modern robot palletizers achieve cycle times of under 30 seconds per cycle, significantly enhancing throughput in production lines. Flexibility is equally vital—robotic systems should be adaptable enough to handle various package sizes and shapes without extensive downtime. A survey by the Association for Advancing Automation highlights that over 60% of manufacturing companies prioritize the ability to quickly reprogram and adapt palletizing solutions to meet changing production demands. By focusing on these technical specifications, businesses can select a robot palletizer that not only meets their current needs but also provides scalability for future growth.

| Specification | Description | Importance |

|---|---|---|

| Payload Capacity | The maximum weight the robot can handle during palletizing. | High |

| Speed | The number of cycles the robot can perform per hour. | Medium |

| Reach | The maximum distance the robot can operate effectively. | High |

| Flexibility | Ability to handle different product types and sizes. | High |

| Integration | Ease of connecting with existing production lines. | Medium |

| Energy Consumption | Amount of energy used during operations. | Medium |

| Footprint | The amount of space the robot occupies. | Low |

| Safety Features | Integrated measures to ensure operator safety. | High |

| Maintenance Requirements | Frequency and ease of robot maintenance. | Medium |

| Software Compatibility | Compatibility with existing control systems and software. | High |

When considering the cost of robot palletizers, it's crucial to evaluate the return on investment (ROI) they offer. The initial expenditure for advanced robotics may seem daunting, but the long-term benefits often outweigh these costs. For instance, fully integrated automation solutions can significantly reduce labor costs and enhance productivity. With the global logistics automation market projected to reach $81.5 billion by 2033 and an impressive CAGR of 10.20% during the forecast period, investing in robotics becomes not only a strategic choice but also a necessary one for businesses aiming to stay competitive.

Additionally, the variety of robot palletizers available can cater to different production needs. From FFS machines that streamline the forming, filling, and sealing process to other automated solutions for labeling and packaging, businesses can select equipment that aligns closely with their operational demands. As automation demands rise across various industries, selecting the right robot palletizer can lead to improved efficiency and a notable reduction in delivery costs, ultimately contributing to a healthier bottom line.

When selecting the best robot palletizer for your business, manufacturer support and maintenance services play a crucial role in ensuring smooth operations. Reliability is key; look for manufacturers that provide comprehensive training for your staff, as well as easy access to technical support. This assistance can significantly reduce downtime and allow your team to maximize the capabilities of the palletizer. Make sure to inquire about the response times for service requests — swift support can save businesses both time and money.

Another critical factor is the availability of spare parts and routine maintenance services. A good manufacturer will offer a readily available inventory of parts to ensure rapid repairs and keep your robot palletizer running efficiently. Additionally, pre-scheduled maintenance services can help prevent unexpected breakdowns and prolong the life of the equipment. As you weigh your options, prioritize manufacturers that demonstrate a commitment to after-sales service, as this can greatly enhance the overall value of your investment.

Finally, consider the customization options available with each manufacturer. Some may offer tailored maintenance packages or specialized upgrades, which can be significant for meeting your specific production needs. Aligning these services with your operational goals will ultimately lead to a more productive and cost-effective solution for your business.