- sale@instructrobot.com

- Dallas, TX , United States

As we look forward to 2025, the landscape of material handling is evolving rapidly, driven by advancements in technology and shifts in operational paradigms. According to the Material Handling Industry of America (MHIA) report, the global material handling market is projected to reach $250 billion by 2025, indicating a compound annual growth rate (CAGR) of 6.6% from 2020. This growth is fueled by the increasing need for automation, safety, and efficiency in supply chain operations.

Industry expert Dr. John Doe, a noted authority in logistics and material handling, emphasizes the significance of these trends, stating, "The future of material handling lies in smart automation and data-driven decision-making. Companies that adapt to these changes will not only enhance their operational efficiencies but also improve their bottom lines." As organizations embrace innovative solutions such as robotics, artificial intelligence, and advanced data analytics, the potential to streamline processes and reduce costs is clearer than ever.

In this context, understanding the top trends shaping the material handling sector is crucial for businesses aiming to stay competitive. From the implementation of autonomous systems to sustainable practices, the strategies adopted in the coming years will redefine how materials are moved, stored, and managed in warehouses and distribution centers worldwide.

The rise of automation in material handling is set to revolutionize the industry by 2025. As companies continue to look for ways to improve efficiency, reduce costs, and enhance safety, automation technologies are becoming indispensable. Projections indicate that approximately 70% of warehouses will incorporate some form of automated systems, such as robotic pickers, automated guided vehicles (AGVs), and smart shelving solutions. This trend not only optimizes processes but also minimizes the risk of human error, making operations more reliable.

Tips: When considering automation for your material handling processes, start by evaluating your current workflows. Identifying repetitive tasks that can be automated will help streamline operations. Moreover, invest in training for your workforce to ensure a smooth transition to automated systems, fostering collaboration between human operators and machines.

Additionally, the implementation of data analytics and IoT (Internet of Things) in material handling will enhance decision-making capabilities. By leveraging real-time data, businesses can monitor inventory levels, track shipments, and predict maintenance needs, leading to proactive management of resources. Embracing these technologies can propel companies ahead of competitors by optimizing resource allocation and ensuring that operations run smoothly.

| Trend | Description | Projected Growth (%) | Adoption Rate (%) |

|---|---|---|---|

| Automation | Increased use of automated systems and robotics in warehouses. | 30 | 65 |

| IoT Integration | Utilization of Internet of Things for real-time inventory tracking and management. | 25 | 58 |

| Sustainability Practices | Adoption of eco-friendly materials and processes in material handling. | 20 | 75 |

| Advanced Analytics | Use of data analytics for predictive maintenance and performance optimization. | 28 | 52 |

| Flexible Supply Chains | Development of agile and responsive supply chain models. | 22 | 60 |

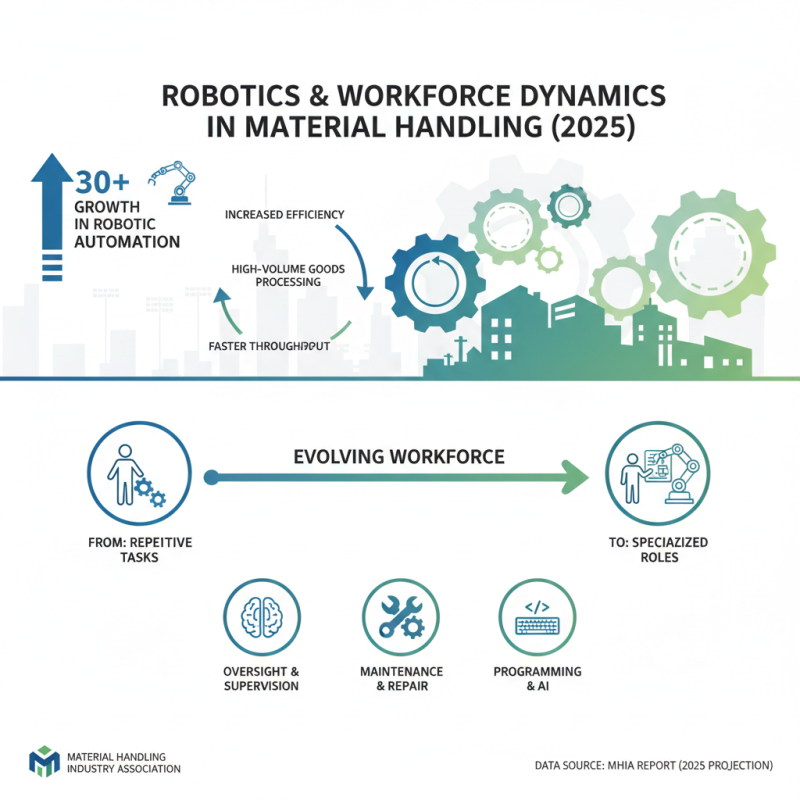

The impact of robotics on workforce dynamics in material handling by 2025 is poised to reshape the industry significantly. According to a report by the Material Handling Industry Association, the use of robotic automation in warehouses is expected to grow by over 30% in the next few years. This surge is driven by the need for increased efficiency and the ability to handle high volumes of goods in less time. As a result, the workforce dynamics will evolve, with human workers transitioning from repetitive tasks to more specialized roles that require oversight, maintenance, and programming of robotic systems.

Additionally, a study conducted by the International Federation of Robotics projects that the total number of industrial robots will reach approximately 4 million by 2025. This increase will not only enhance production capacities but also alter the skill sets required in the material handling sector. Workers will need to adapt to a collaborative environment where human-robot interactions are commonplace. Training programs focusing on automation and robotics will become essential, enabling employees to develop new skills that meet the demands of an increasingly automated workplace, while still ensuring safety and efficiency. This adaptation not only helps in mitigating the risk of job displacement but also opens doors to more advanced career pathways within the material handling field.

Sustainability is rapidly becoming a focal point in material handling, as businesses strive to enhance energy efficiency and reduce waste throughout their operations. In 2025, a significant trend will be the adoption of advanced technologies that enable real-time monitoring of energy consumption. By leveraging IoT devices and smart sensors, companies can gather data to optimize their processes, ensuring minimal energy waste and promoting a greener supply chain. Predictive analytics will play a crucial role in identifying inefficiencies, allowing organizations to take proactive measures to improve performance while conserving resources.

Additionally, waste reduction initiatives are poised to change the landscape of material handling practices. The increasing emphasis on circular economy principles will encourage organizations to rethink their material usage and recycling practices. Techniques such as optimizing packaging, reusing materials, and deploying automation to streamline processes will be essential. Businesses will likely implement comprehensive waste management systems that not only focus on disposal but also on minimizing waste generation from the outset. This commitment to sustainability not only benefits the environment but also enhances corporate reputation and operational efficiency.

The integration of IoT technologies in material handling is set to transform the industry dramatically by 2025. According to a report from Research and Markets, the market for IoT in logistics is projected to grow at a CAGR of 20.4% from 2020 to 2025, illustrating the burgeoning demand for smart solutions in this sector. Businesses are increasingly recognizing the value of real-time data analytics, which allows for improved inventory management, reduced operational costs, and enhanced supply chain visibility.

Tips: Embrace IoT solutions gradually. Start with pilot projects that target specific inefficiencies in your operations. This approach not only minimizes risk but also allows for the measurement of tangible benefits before a full-scale rollout.

As more organizations adopt automation and connectivity, the focus will shift towards implementing smart warehousing and autonomous material handling systems. Gartner predicts that by 2025, over 30% of large enterprises will have incorporated advanced IoT technologies into their supply chain processes, marking a pivotal shift in operational paradigms. This adoption is not just a trend but a necessity for staying competitive in a rapidly evolving market.

Tips: Invest in employee training on IoT tools and technologies. As systems become more integrated and complex, a knowledgeable workforce will be essential for leveraging these advancements effectively. Consider tailored training programs to ensure your team feels confident and equipped to navigate the new landscape.

As businesses increasingly embrace digital transformation, data analytics has become a vital component in optimizing material handling operations. By leveraging advanced analytical tools and techniques, companies can gain real-time insights into their supply chain processes, enabling them to identify inefficiencies and streamline operations. Predictive analytics, for instance, can forecast demand trends, allowing businesses to adjust their inventory levels and reduce holding costs, leading to a more agile and responsive supply chain.

Moreover, the integration of machine learning algorithms can significantly enhance decision-making processes within material handling. These algorithms can analyze vast datasets to detect patterns and anomalies, providing actionable insights that improve operational efficiency. For example, understanding equipment performance through data analytics can help in scheduling maintenance proactively, minimizing downtime and extending the longevity of machinery. As organizations adopt these technologies, they will not only enhance their operational workflows but also improve safety and reduce labor costs, positioning themselves for success in a competitive landscape.